Discussion Overview

The discussion revolves around the calculation of reduced stiffness in a front suspension system, specifically addressing the relationship between vertical and inclined strokes and the factors influencing stiffness. The scope includes technical reasoning and mathematical relationships related to mechanical systems.

Discussion Character

- Technical explanation, Mathematical reasoning, Debate/contested

Main Points Raised

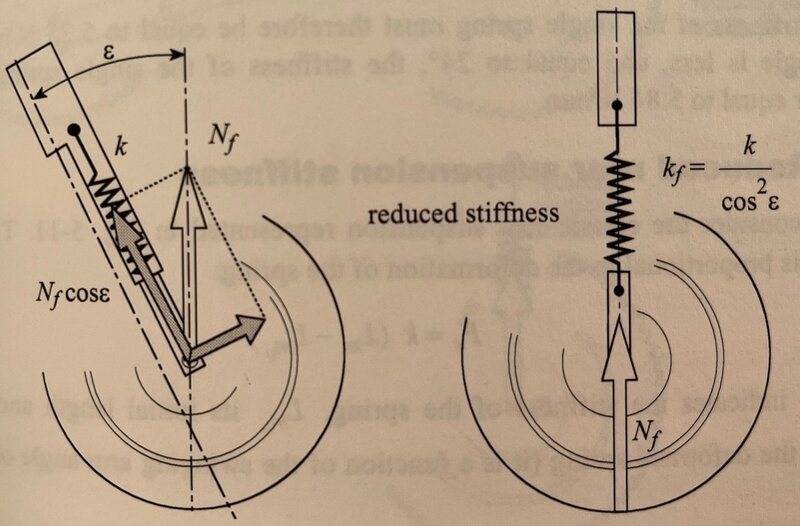

- One participant, Semat10, seeks clarification on how to derive the reduced stiffness formula, specifically questioning the term k_f = k/cos²E.

- Another participant mentions that the vertical stroke is equal to the inclined stroke multiplied by the cosine of angle ε.

- A different participant expresses confusion about the origin of the square in the formula, indicating a lack of understanding regarding its derivation.

- One participant proposes that the force of the vertical spring must be less than N_f*cos(ε), suggesting that the vertical stroke is proportionally smaller than the inclined stroke, which is accounted for twice in their reasoning.

- The same participant presents a formula for vertical stiffness, k_vertical = N_f / Vertical stroke, and relates it to inclined stroke using the cosine factor.

- There is a question posed regarding the ratio of vertical stiffness to inclined stiffness, k_vertical/k_inclined, indicating an exploration of relationships between these quantities.

Areas of Agreement / Disagreement

Participants express differing levels of understanding regarding the derivation of the stiffness formula, with some agreeing on the relationship between vertical and inclined strokes while others remain uncertain about specific aspects, particularly the squared term.

Contextual Notes

Participants have not fully resolved the mathematical steps leading to the inclusion of the square in the stiffness formula, and there are assumptions regarding the definitions of vertical and inclined strokes that remain unclarified.