gogogsr

- 9

- 0

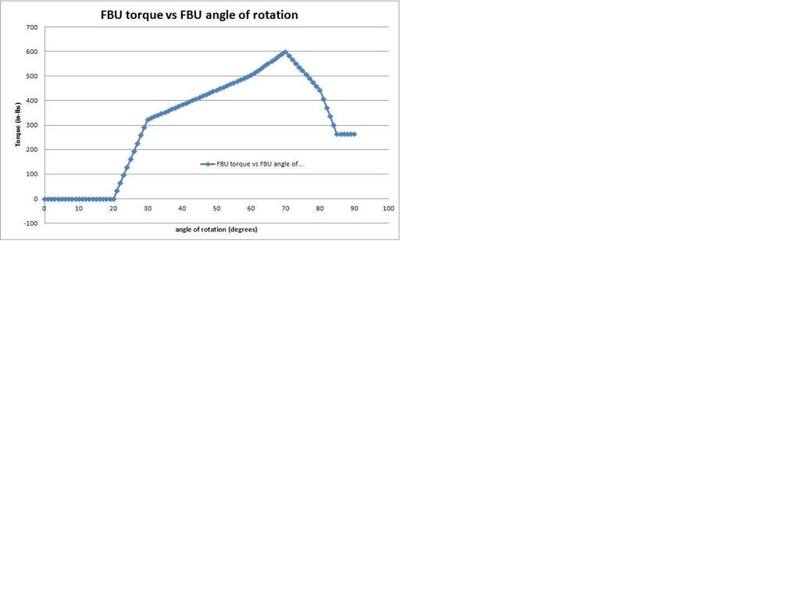

Hey guys, I'm making a test jig that needs to simulate a train caliper. The test jig consist of an arm that rotates 90 degrees. The jig must give a certain amount of torque at every degrees (see graph below). I was thinking on making a cam with an eccentric roller follower and die spring. The thing is I'm having a hard time to design the cam from the torque values. I've been able to simulate a sliding cam easily but when it comes to a radial cam its a lot more tricky, everything works with my calculations, except the pressure angle which is almost always 10 time smaller, so the torque is way less then wanted. I'm not sure if i need to determine the envelop of the cam depending on the previous point calculated or not.Any help would be appreciated.

Thanks guys

Thanks guys