Discussion Overview

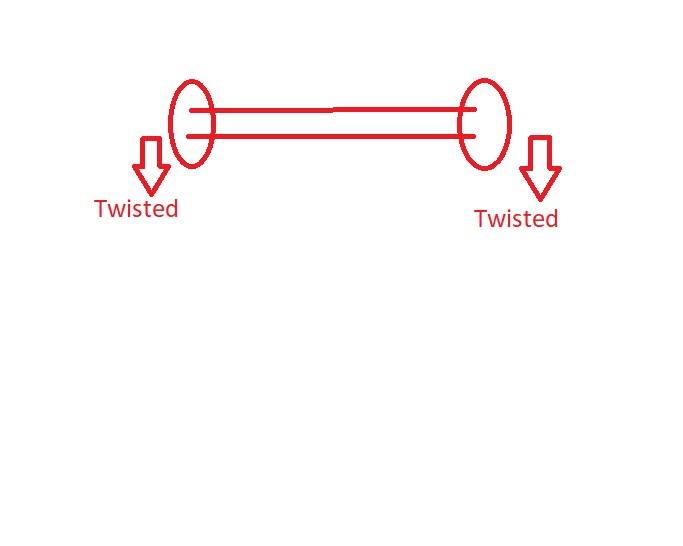

The discussion revolves around the feasibility and implications of using two 6 Gauge wires or two 22 Gauge wires twisted together as a substitute for a single 12 Gauge electrical wire. Participants explore the electrical properties, safety concerns, and compliance with building codes related to this substitution.

Discussion Character

- Technical explanation

- Debate/contested

- Mathematical reasoning

Main Points Raised

- Some participants note that 6AWG wire is thicker than 12AWG wire and can carry the same current, suggesting no need to double-up wires.

- Others emphasize the importance of checking local building codes, indicating that 12AWG is often the minimum size required for installations.

- A participant mentions that paralleling conductors can theoretically meet capacity requirements but warns that differences in resistance can lead to uneven current distribution.

- One participant questions the appropriateness of using American Wire Gauge (AWG) instead of SI units, suggesting a preference for standard measurements.

- Another participant discusses the resistance characteristics of wire, explaining that the resistance doubles for every 3 AWG increment, raising questions about the necessary gauge to achieve equivalent resistance when paralleling wires.

- A rule of thumb is provided, indicating that to replace AWG 12, one could use two AWG 15 or four AWG 18, or eight AWG 21, or ten AWG 22 wires.

Areas of Agreement / Disagreement

Participants express differing views on the safety and practicality of using twisted wires as a substitute for 12 Gauge wire. There is no consensus on the best approach, and multiple competing views remain regarding the implications of using different wire gauges.

Contextual Notes

Some limitations include the potential confusion arising from the original question edits and the varying interpretations of wire gauge implications on resistance and current-carrying capacity.