Urika

- 8

- 2

- Homework Statement

- MANUFACTURE & MATERIALS

- Relevant Equations

- None

SCREENSHOT OF FIGURE ATTACHED!

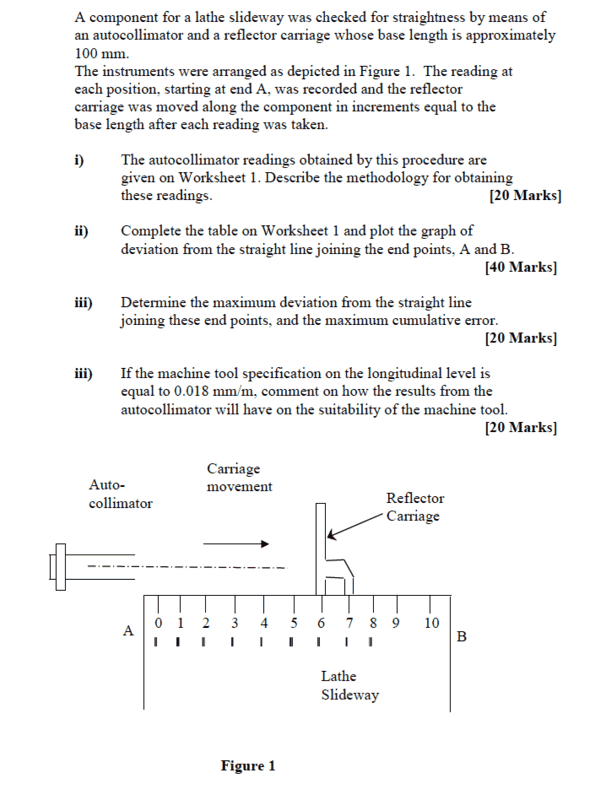

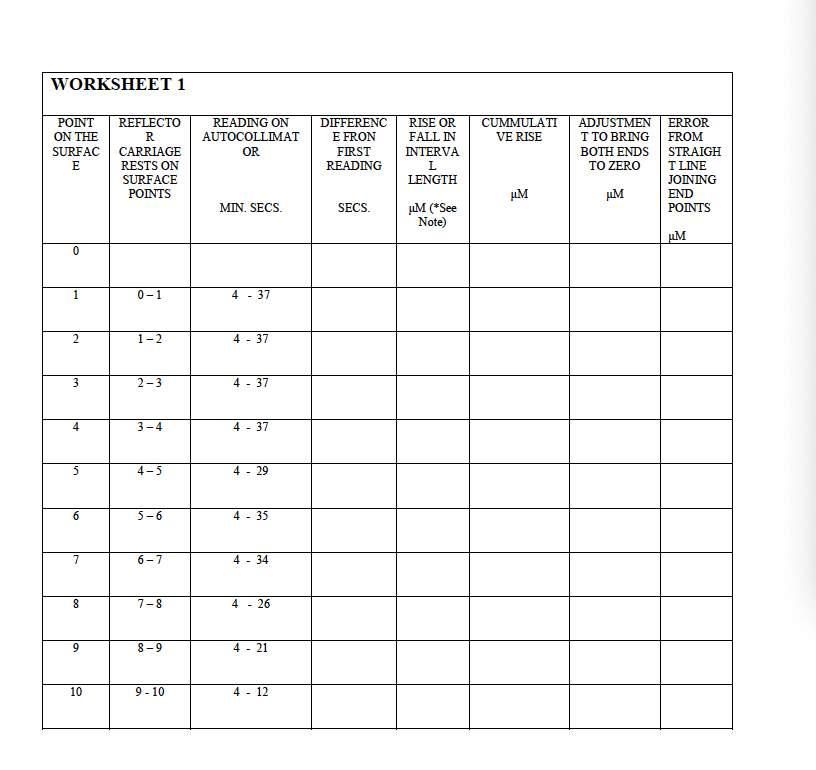

A component for a lathe slideway was checked for straightness by means of an autocollimator and a reflector carriage whose base length is approximately 100 mm.The instruments were arranged as depicted in Figure 1. The reading at each position, starting at end A, was recorded and the reflector carriage was moved along the component in increments equal to the base length after each reading was taken.i) The autocollimator readings obtained by this procedure are given on Worksheet 1. Describe the methodology for obtaining these readings.

ii) Complete the table on Worksheet 1 and plot the graph of deviation from the straight line joining the end points, A and B.

iii) Determine the maximum deviation from the straight line joining these end points, and the maximum cumulative error.

iii) If the machine tool specification on the longitudinal level is equal to 0.018 mm/m, comment on how the results from the autocollimator will have on the suitability of the machine tool.https://www.physicsforums.com/attachments/274451

https://www.physicsforums.com/attachments/274451

https://www.physicsforums.com/attachments/274451

A component for a lathe slideway was checked for straightness by means of an autocollimator and a reflector carriage whose base length is approximately 100 mm.The instruments were arranged as depicted in Figure 1. The reading at each position, starting at end A, was recorded and the reflector carriage was moved along the component in increments equal to the base length after each reading was taken.i) The autocollimator readings obtained by this procedure are given on Worksheet 1. Describe the methodology for obtaining these readings.

ii) Complete the table on Worksheet 1 and plot the graph of deviation from the straight line joining the end points, A and B.

iii) Determine the maximum deviation from the straight line joining these end points, and the maximum cumulative error.

iii) If the machine tool specification on the longitudinal level is equal to 0.018 mm/m, comment on how the results from the autocollimator will have on the suitability of the machine tool.https://www.physicsforums.com/attachments/274451

Last edited: