some bloke

- 283

- 99

- TL;DR

- I'm looking to build a charcoal forge for my garden - and I have a thought for a redesign.

I'm going to be taking up some ironwork as a hobby again, which I dabbled in a few years back. I had a forge made of a brake hub, and it worked quite well. I'm now considering a redesigned charcoal forge and I thought I would run an idea by you guys, who are probably more knowledgeable than me on the nature of fire!

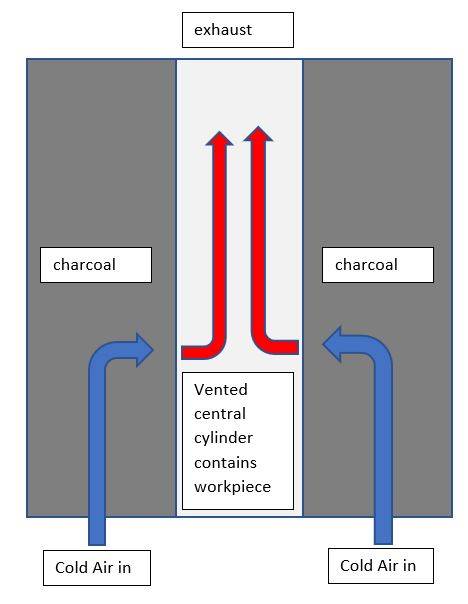

The idea is to have 2 cylinders, one inside the other. the inside of the large one is filled with burning charcoal, and the inner one is where the workpiece is placed. the inner one is perforated full of holes, to let the hot gases pass through.

My theory is that the hot gases from the charcoal can be pumped into the inner cylinder, heating the workpiece as the air feed makes the charcoal burn hotter. This theory relies entirely on the idea that the gases released by the charcoal will make it hot enough to make steel glow, without actual contact with the charcoal.

The outer cylinder would be capped and would need a constant feed of air to keep it burning. The inner one is perforated and open at the top. The outer cylinder would have an air-feed from a fan of sorts to pump the air through.

I suspect that the air wouldn't heat up enough to make this effective. My goal is to make something akin to a gas forge, but without the need for a gas bottle and the potential explosion that goes with it! I'm confident in my abilities to make a pot of fire, but not in working with gas!

The idea is to have 2 cylinders, one inside the other. the inside of the large one is filled with burning charcoal, and the inner one is where the workpiece is placed. the inner one is perforated full of holes, to let the hot gases pass through.

My theory is that the hot gases from the charcoal can be pumped into the inner cylinder, heating the workpiece as the air feed makes the charcoal burn hotter. This theory relies entirely on the idea that the gases released by the charcoal will make it hot enough to make steel glow, without actual contact with the charcoal.

The outer cylinder would be capped and would need a constant feed of air to keep it burning. The inner one is perforated and open at the top. The outer cylinder would have an air-feed from a fan of sorts to pump the air through.

I suspect that the air wouldn't heat up enough to make this effective. My goal is to make something akin to a gas forge, but without the need for a gas bottle and the potential explosion that goes with it! I'm confident in my abilities to make a pot of fire, but not in working with gas!