DaveC426913

Gold Member

2025 Award

- 24,354

- 8,566

- TL;DR

- Is it geometrically possible to have an extensible scissor arm that tapers from large to small?

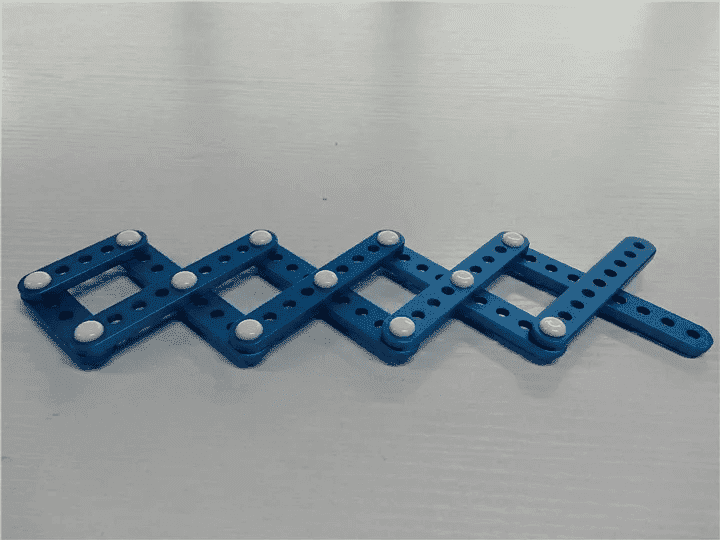

This is what I am calling an extensible scissor arm:

This one is symmetrical - the same breadth along this entire length. I'd like to design one that narrows from one end to the other.

I realize that will change the geometry of each section - they will get shorter and shorter - but is it doable?

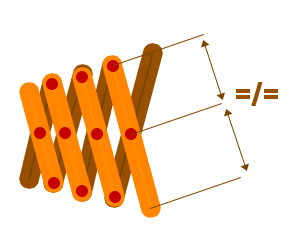

When I imagined it in my head, it was fairly straightforward - a simple incremental scaling-down of the parts, as well as moving each central pivot asymmetrically:

But the moment I started sketching it out, it became quite a bit more complicated. The lengths of each spar are not a simple relationship - the scaling factor is shared between left and right (orange and brown) spars in a way that is not immediately apparent. I'll have to experiment, but I'm sort of going by trial and error.I have a gut feeling that the problem I will run into is that the extension amount will be "conserved" from left to right - i.e. a small extension at the right will propagate to form a large extension on the left (like a wave breaking on a sloping beach). The left end will reach its extension limit long before the right end will, meaning its extensibility will be wasted (overengineered).EDIT: Yeah. The more I think about it, the more I see that the maximum extensibility is determined by the smallest arm. Any arms larger than the smallest are wasted. Which is why there's no such thing as a tapered scissor arm.

But the moment I started sketching it out, it became quite a bit more complicated. The lengths of each spar are not a simple relationship - the scaling factor is shared between left and right (orange and brown) spars in a way that is not immediately apparent. I'll have to experiment, but I'm sort of going by trial and error.I have a gut feeling that the problem I will run into is that the extension amount will be "conserved" from left to right - i.e. a small extension at the right will propagate to form a large extension on the left (like a wave breaking on a sloping beach). The left end will reach its extension limit long before the right end will, meaning its extensibility will be wasted (overengineered).EDIT: Yeah. The more I think about it, the more I see that the maximum extensibility is determined by the smallest arm. Any arms larger than the smallest are wasted. Which is why there's no such thing as a tapered scissor arm.

I'd still be interested in feedback, in case there's a way out of this trap I have not divined yet.

This one is symmetrical - the same breadth along this entire length. I'd like to design one that narrows from one end to the other.

I realize that will change the geometry of each section - they will get shorter and shorter - but is it doable?

When I imagined it in my head, it was fairly straightforward - a simple incremental scaling-down of the parts, as well as moving each central pivot asymmetrically:

I'd still be interested in feedback, in case there's a way out of this trap I have not divined yet.

Last edited: