- #1

Miss Mechy

- 3

- 0

Hi, I am trying to work out the calliper breaking force of a small motorsport car i.e. the moment force needed to be exerted at a given distance on the wheel to bring the car to a stop.

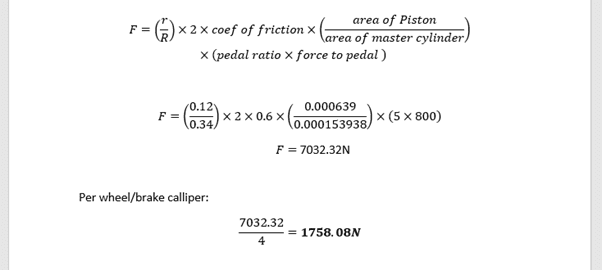

I initial calculated the force using an equation which highlighted the specific capabilities of the brake calliper, along with the input force of the pedals (Disregarding weight distribution) as shown below:

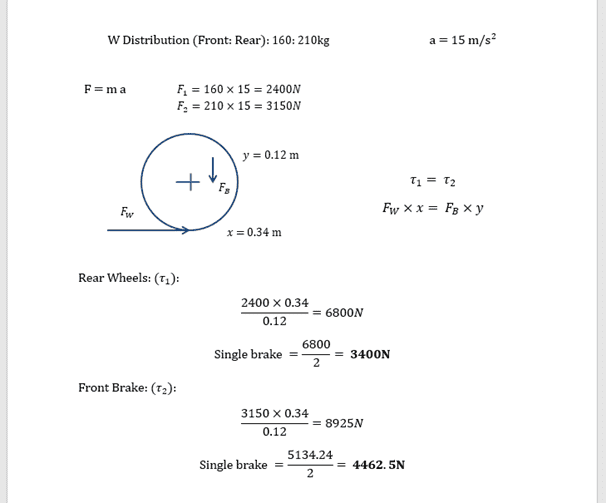

I then tried to validate this value by using a more basic equation, using the g and weight of the car, with no specific brake calliper parameters.

Although two completely different solutions, should both not be of similar value? Are my calculations correct for either of the solutions? Or if in fact they are does anyone know why they are so different?

(I am aware wheel lock is not made apparent in either solutions)

I initial calculated the force using an equation which highlighted the specific capabilities of the brake calliper, along with the input force of the pedals (Disregarding weight distribution) as shown below:

I then tried to validate this value by using a more basic equation, using the g and weight of the car, with no specific brake calliper parameters.

Although two completely different solutions, should both not be of similar value? Are my calculations correct for either of the solutions? Or if in fact they are does anyone know why they are so different?

(I am aware wheel lock is not made apparent in either solutions)