Billie_HK

- 1

- 0

ABAQUS provides geometric restrictions such as a planer, rotational, and other symmetric,

but there is no axis symmetric restriction.

I know that the 2D axis symmetric element model could be possible to make in PART section.

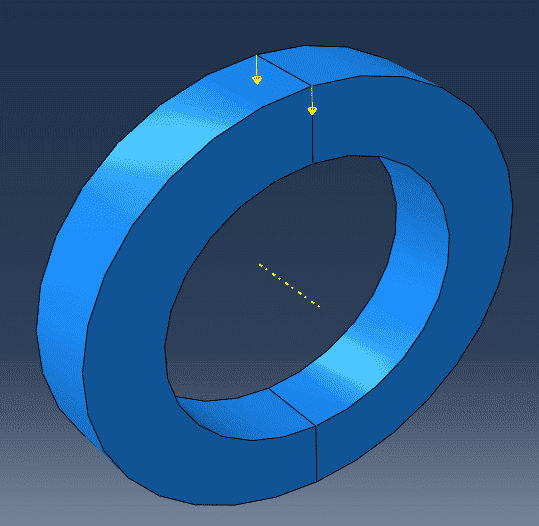

But I want to know that a full 3D element model could be optimized by axis symmetric, because the load and boundary condition is applied in a specific zone like the figure below. (If the load is applied 2D model, it will apply to all elements of the same orbit location.

Is there a software or methodology that this can be implemented?

but there is no axis symmetric restriction.

I know that the 2D axis symmetric element model could be possible to make in PART section.

But I want to know that a full 3D element model could be optimized by axis symmetric, because the load and boundary condition is applied in a specific zone like the figure below. (If the load is applied 2D model, it will apply to all elements of the same orbit location.

Is there a software or methodology that this can be implemented?