Fadzli

- 7

- 0

Hi all,

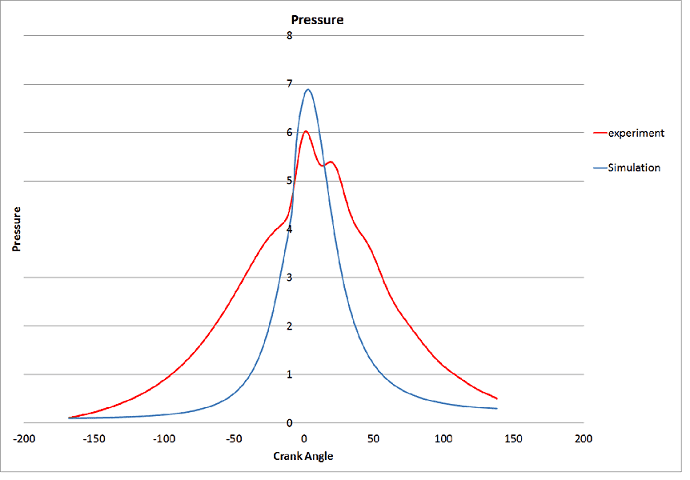

I’m currently investigating the engine in-cylinder pressure by simulation and experimental method. All inputs parameters in the simulation were exactly follow the engine technical specification (engine geometry, compression ratio, fuel injection parameters, initial pressure and temperature etc.) When both data were plotted, they are significantly different (please refer to the attached picture). Based on my literature study, most of the pressure vs crank angle graph are almost similar to my simulation result. So any idea why this is happen? Or at least what else parameters need to consider in order to validate these two results?

I’m currently investigating the engine in-cylinder pressure by simulation and experimental method. All inputs parameters in the simulation were exactly follow the engine technical specification (engine geometry, compression ratio, fuel injection parameters, initial pressure and temperature etc.) When both data were plotted, they are significantly different (please refer to the attached picture). Based on my literature study, most of the pressure vs crank angle graph are almost similar to my simulation result. So any idea why this is happen? Or at least what else parameters need to consider in order to validate these two results?