- #1

Cire Venn

- 18

- 2

I apologize if this is in the wrong thread, I'm new.

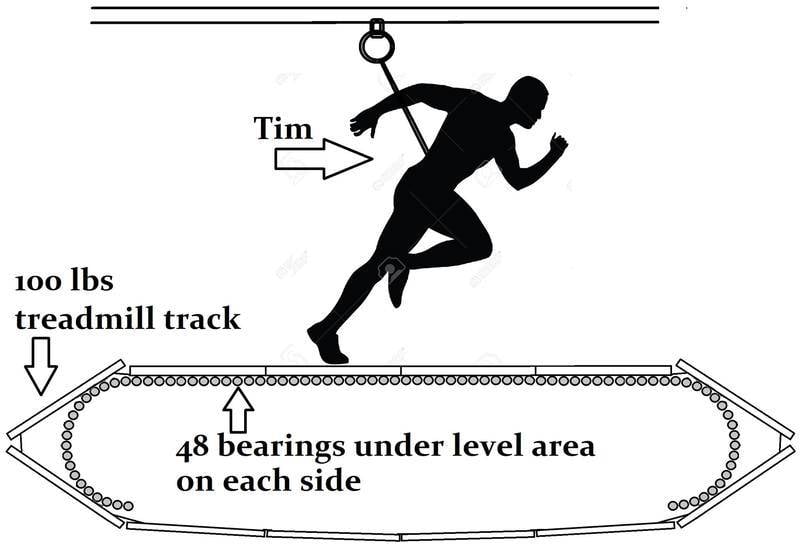

I need to figure out how hard it would be for Jim to move the treadmill treads along its track of bearings. This isn't for homework, it's just something I want to know.

Jim weighs 160 lbs.

The rope isn't holding him up, it's there for him to lean forward against so he moves the treadmill with his legs instead of moving himself.

The entire treadmill track weighs 100 lbs, not each individual piece.

The reason I know this is a reasonable question to ask is because the weight on each bearing while it needs to turn is much less than the weight on skateboard bearings which normal people move all the time with one leg while standing on the skateboard. The bearings should only need to spin under 10 lbs of weight (assuming the weight of the entire thing was on one section, which is a vast over exaggeration) when normal skateboard bearings spin under /40 lbs each/.

A skateboard has four wheels and people on skateboards can push themselves along with one leg while standing on the skateboard. Their body weight divided by the number of wheels (160 divided by 4 = 40 pounds per wheel) and since we know moving a skateboard works in this manner with that kind of weight on each of the bearings. So for the treadmill if we divide 260 (weight of treadmill track plus weight of person) by 24 (the number of bearings supporting just /one/ of the treadmill tracks, assuming the worst that the weight of everything is on just one area) we get 10 pounds of weight per bearing, which is still 30 pounds less than the weight on the bearings of a normal skateboard so this seems to show to me that it can't be /that/ hard to move this kind of treadmill manually.

The bearings are the same type used in regular skateboards type-608 bearings.

Let me know if you need more information than is printed in the picture.

I need to figure out how hard it would be for Jim to move the treadmill treads along its track of bearings. This isn't for homework, it's just something I want to know.

Jim weighs 160 lbs.

The rope isn't holding him up, it's there for him to lean forward against so he moves the treadmill with his legs instead of moving himself.

The entire treadmill track weighs 100 lbs, not each individual piece.

The reason I know this is a reasonable question to ask is because the weight on each bearing while it needs to turn is much less than the weight on skateboard bearings which normal people move all the time with one leg while standing on the skateboard. The bearings should only need to spin under 10 lbs of weight (assuming the weight of the entire thing was on one section, which is a vast over exaggeration) when normal skateboard bearings spin under /40 lbs each/.

A skateboard has four wheels and people on skateboards can push themselves along with one leg while standing on the skateboard. Their body weight divided by the number of wheels (160 divided by 4 = 40 pounds per wheel) and since we know moving a skateboard works in this manner with that kind of weight on each of the bearings. So for the treadmill if we divide 260 (weight of treadmill track plus weight of person) by 24 (the number of bearings supporting just /one/ of the treadmill tracks, assuming the worst that the weight of everything is on just one area) we get 10 pounds of weight per bearing, which is still 30 pounds less than the weight on the bearings of a normal skateboard so this seems to show to me that it can't be /that/ hard to move this kind of treadmill manually.

The bearings are the same type used in regular skateboards type-608 bearings.

Let me know if you need more information than is printed in the picture.

Last edited: