Discussion Overview

The discussion revolves around the computation of the curvature and shape of a surface for a mechanical design involving a rocker arm and a poppet valve stem. Participants explore the mechanics of rolling versus sliding contact in this context, particularly focusing on the design implications for a roller rocker engagement area.

Discussion Character

- Technical explanation

- Debate/contested

- Exploratory

Main Points Raised

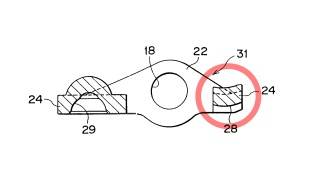

- One participant seeks to design a roller rocker that rolls over a flat poppet valve stem instead of sliding, questioning how to compute the necessary curvature.

- Another participant suggests that the rocker needs a curve similar to a gear tooth involute, emphasizing the importance of the contact angle to prevent valve rotation.

- A participant expresses uncertainty about the necessity of a rounded valve stem end, proposing that a flat end could suffice, while also questioning the implications of side thrust in this design.

- One participant compares the situation to a spur gear rolling along a rack, noting that a square-cut stem end would not facilitate rolling contact.

- Another participant raises doubts about the prevalence of sliding contact in automotive applications, suggesting that rollers are often used to mitigate friction.

- A participant recounts historical practices in engine design, noting that sliding contact was common when gas was cheaper, but that modern designs have shifted towards roller mechanisms to reduce friction losses.

- One participant mentions that modern engines often use roller rockers, but questions whether they slide or roll on the valve stem, and seeks guidance on how to graph the necessary curve for design purposes.

Areas of Agreement / Disagreement

Participants express differing views on the necessity and feasibility of rolling versus sliding contact in the design of the rocker and valve stem interface. There is no consensus on the optimal design approach or the implications of using a flat versus rounded stem end.

Contextual Notes

Participants highlight various assumptions, such as the contact angle and the implications of different stem shapes, which remain unresolved. The discussion also reflects a lack of clarity on the mechanical behavior of the components involved.

Who May Find This Useful

Engineers and designers interested in mechanical systems, particularly those focused on valvetrain design and friction reduction in automotive applications, may find this discussion relevant.