Discussion Overview

The discussion revolves around calculating the static pressure drop in a laminar flow channel, specifically under conditions of steady state and incompressible flow. Participants explore methods for determining this pressure drop, considering the geometry of the channel and the properties of the fluid involved.

Discussion Character

- Technical explanation, Conceptual clarification, Debate/contested

Main Points Raised

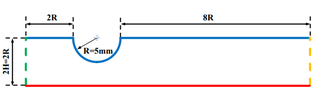

- One participant seeks assistance in calculating the static pressure drop across a fully developed laminar flow channel, having already determined the inlet velocity based on the Reynolds number.

- Another participant suggests solving the Navier-Stokes equations, potentially using numerical methods, and mentions that an analytical solution can be obtained for a simpler case of rectilinear flow between parallel plates.

- A third participant clarifies the problem's assumptions, including laminar flow, steady state, constant density, and fully developed flow, and hints at using the Darcy Friction Factor and Moody Diagram as part of the solution approach.

- A later reply requests a more precise statement of the problem to better understand the context and requirements.

Areas of Agreement / Disagreement

Participants express differing views on the methods to calculate the pressure drop, with some suggesting numerical solutions and others proposing analytical approaches. The discussion remains unresolved regarding the best method to apply.

Contextual Notes

Participants have not fully defined the channel geometry, which may affect the calculations. There is also a lack of consensus on the specific assumptions and parameters needed for the pressure drop calculation.