Discussion Overview

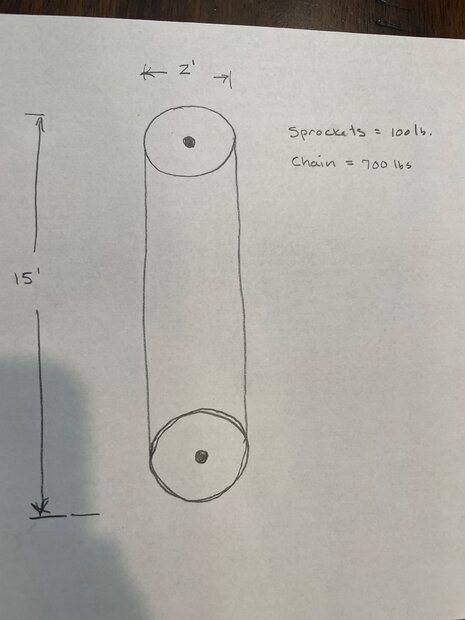

The discussion revolves around calculating the horsepower and torque required to rotate a dual sprocket/chain system that will intermittently lift and rotate buckets filled with liquid. The focus includes theoretical modeling of the system's mechanics, considerations of weight distribution, and the implications of acceleration and friction on power requirements.

Discussion Character

- Exploratory

- Technical explanation

- Debate/contested

- Mathematical reasoning

Main Points Raised

- One participant seeks to determine the horsepower and torque needed for a sprocket/chain system that rotates 5 degrees at a time, with a slow speed and resting periods.

- Another participant questions the weight of the system and suggests that the torque required will depend on the bearing friction and the moment of inertia.

- It is noted that the system will be vertical and will involve lifting buckets filled with liquid, which introduces complexity in torque calculations.

- Participants discuss the importance of acceleration in calculations, with one noting that the power requirement may be low despite the system's weight due to the short rotation and slow speed.

- Concerns are raised about the torque requirements when the load is unbalanced, particularly when half of the buckets are filled.

- There is a discussion about the need for counter-torque during the loading phase, with some participants suggesting that the system may need to handle back-torque effectively.

- One participant proposes a specific calculation for the rotation speed and distance traveled during the rotation.

Areas of Agreement / Disagreement

Participants generally agree on the need to consider various factors such as weight distribution, friction, and acceleration in determining the power requirements. However, there are competing views on the implications of back-torque and how it may affect the motor's performance, indicating that the discussion remains unresolved.

Contextual Notes

Participants mention the complexity of friction in the chain system and the potential for varying torque requirements based on the loading conditions. The discussion also highlights the importance of understanding the mechanics of the system before finalizing calculations.