Discussion Overview

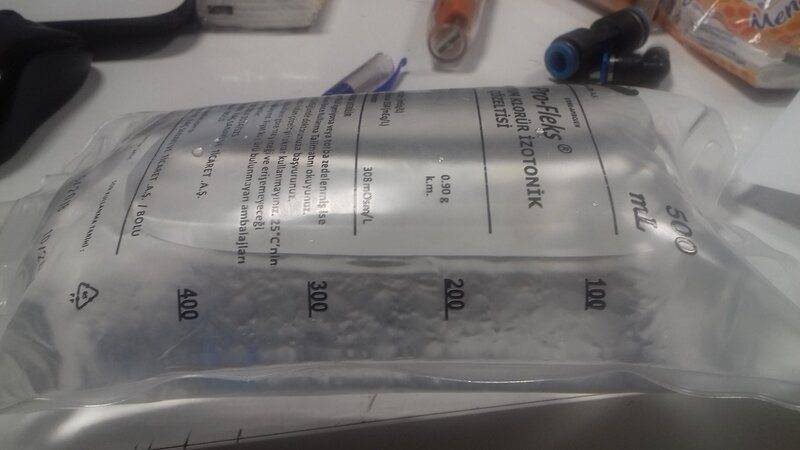

The discussion revolves around calculating the force acting on IV bags in a pharmaceutical lab based on applied pressure. Participants explore the implications of pressure, surface area, and the effects of compressible air in the context of testing the integrity of IV bags. The conversation includes theoretical considerations and practical applications related to the testing process.

Discussion Character

- Exploratory

- Technical explanation

- Conceptual clarification

- Debate/contested

- Experimental/applied

Main Points Raised

- One participant questions whether to use the entire surface area of the IV bag or just the area in contact with the upper plate for calculating force, considering the presence of air above the liquid.

- Another participant explains that compressible air behaves like a spring, affecting the volume of the liquid and the bag during the test.

- A different viewpoint suggests that the pressure at the top of the bag can be derived from the force supplied by the scale divided by the contact area, noting that pressure at the bottom may be slightly higher due to the weight of the liquid.

- Some participants inquire about the purpose of the test, whether it is to assess the yield strength of the bag material, and if there are established standards for such testing.

- Concerns are raised about the non-uniform shape of the IV bag and how that affects force distribution, with references to Young-Laplace law and surface tension.

- One participant proposes calculating the force on the plate by multiplying air pressure by piston area, questioning how much of that force transfers to the bags and whether to include the weight of the plate.

- Another participant suggests that the concept of "force acting on the bags" may not be useful for determining leak thresholds.

- Discussion includes two different conditions for the bag: one being curved and the other flat, with implications for calculating tensile forces and pressure distribution.

Areas of Agreement / Disagreement

Participants express various viewpoints on the calculation methods and implications of pressure on IV bags, with no clear consensus reached on the best approach or the utility of the force measurement for leak testing.

Contextual Notes

Limitations include the lack of clarity on the exact testing standards for IV bags, the dependence on the bag's shape and material properties, and unresolved questions about the relationship between applied force and leak thresholds.