Minghan

- 17

- 2

- TL;DR

- Is there any method to measure the power of the pump?

Want to know how to get the actual power the pump needs.

I can measure the flow rate by the flow meter and count the revolutions of the pump.

But selecting the proper motor for the pump would be a problem.

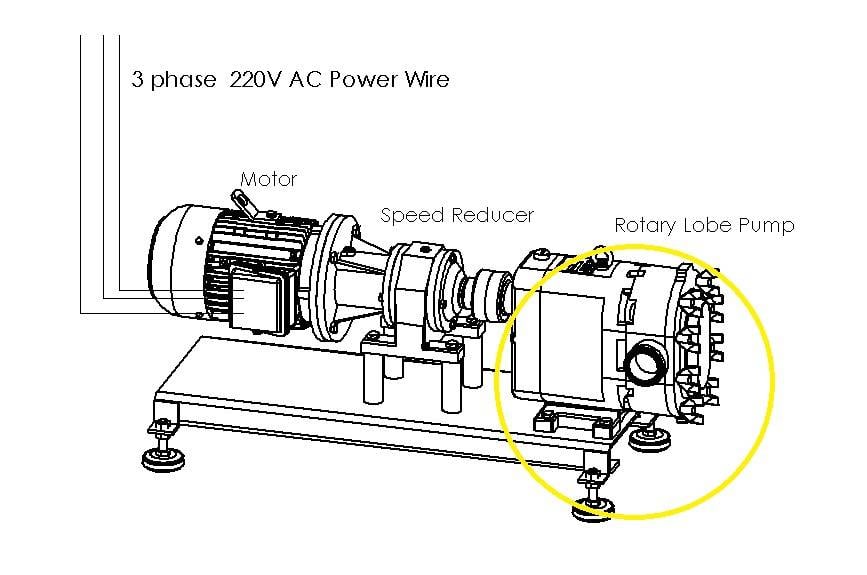

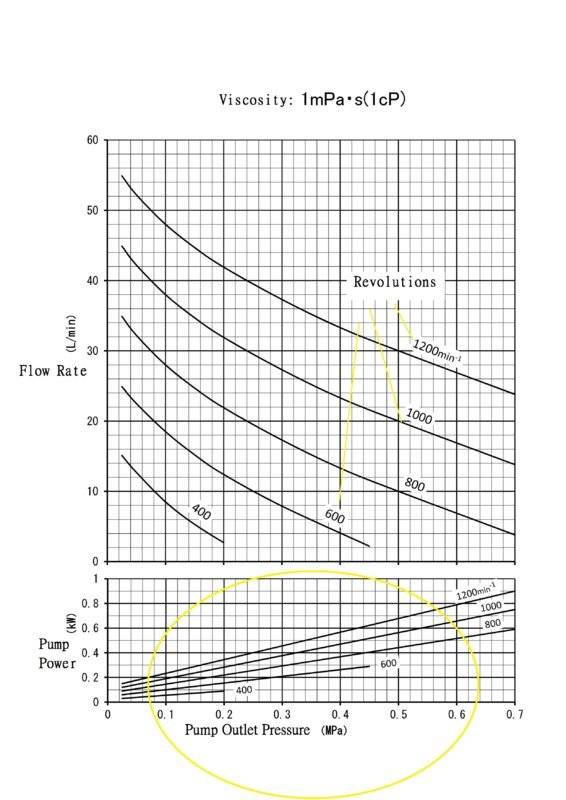

So I want to know how to determine the power of the rotary lobe pump and generate the graph like below.

I can measure the flow rate by the flow meter and count the revolutions of the pump.

But selecting the proper motor for the pump would be a problem.

So I want to know how to determine the power of the rotary lobe pump and generate the graph like below.