gogogsr

- 9

- 0

Hey guys,

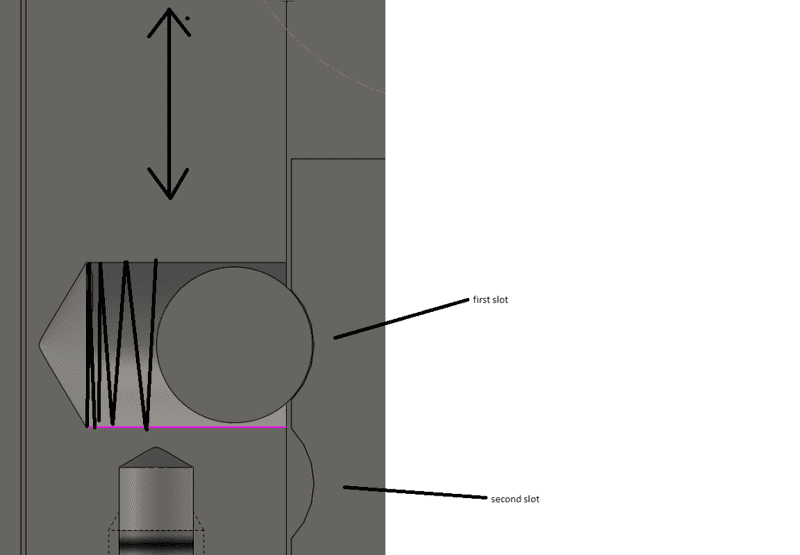

i'm building an apparatus with a sliding pin containing a spring and a ball. I want to lock in two different positions so I've rounded two slots in the housings. I would like to know what is the equation two find the normal force of the spring on the ball depending on the displacement of the pin. I'm having a hard time finding the normal with an equation, i can find it manually by moving the pin at different points and then drawing the tangent and normal to find the angle but i know there must be an equation. the slot diameter is bigger than the ball diameter to make sure it slides easily (meaning the slot and ball are not concentric)Thanks guys

i'm building an apparatus with a sliding pin containing a spring and a ball. I want to lock in two different positions so I've rounded two slots in the housings. I would like to know what is the equation two find the normal force of the spring on the ball depending on the displacement of the pin. I'm having a hard time finding the normal with an equation, i can find it manually by moving the pin at different points and then drawing the tangent and normal to find the angle but i know there must be an equation. the slot diameter is bigger than the ball diameter to make sure it slides easily (meaning the slot and ball are not concentric)Thanks guys