Rx7man

- 425

- 189

I'm looking to build a device that takes a pulse from a piezo crystal and interface it to a microcontroller.. I know the piezo is a very high voltage device, so I need to find some way to make it compatible.. I looked it up on the Arduino site and it seems like a terribly primitive method to use a 1meg resistor in parallel with it.

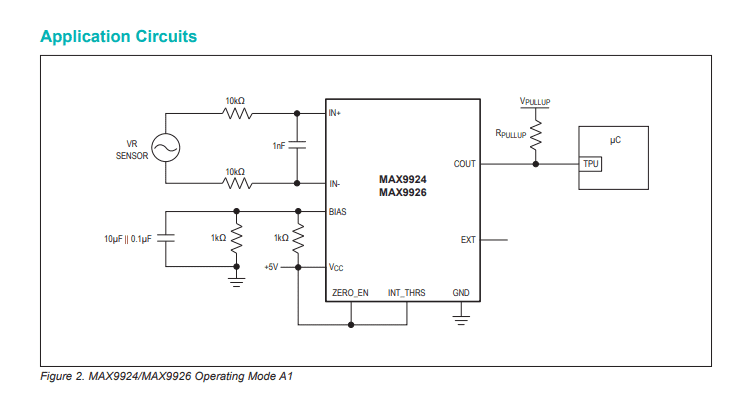

I was thinking perhaps a VR sensor IC chip like the MAX9924 which is capable of some noise filtration, zero crossing detection, and I need them in my project anyhow.

https://datasheets.maximintegrated.com/en/ds/MAX9924-MAX9927.pdf

The application is a diesel engine timing monitor, I'll have a VR sensor on the cam gear (10* per tooth), with a hall effect sensor to sense #1 cylinder position, the Piezo crystal.. Something like what's shown here https://www.amazon.com/dp/B00063Y1LU/?tag=pfamazon01-20I may need to play with the resistor values a bit, start with more resistance and lower it until it works

Open to other ideas, maybe there's a specific chip for this? I didn't see anything when I searched Mouser

I was thinking perhaps a VR sensor IC chip like the MAX9924 which is capable of some noise filtration, zero crossing detection, and I need them in my project anyhow.

https://datasheets.maximintegrated.com/en/ds/MAX9924-MAX9927.pdf

The application is a diesel engine timing monitor, I'll have a VR sensor on the cam gear (10* per tooth), with a hall effect sensor to sense #1 cylinder position, the Piezo crystal.. Something like what's shown here https://www.amazon.com/dp/B00063Y1LU/?tag=pfamazon01-20I may need to play with the resistor values a bit, start with more resistance and lower it until it works

Open to other ideas, maybe there's a specific chip for this? I didn't see anything when I searched Mouser