Discussion Overview

The discussion centers around the calculation of weld stress in a pressure vessel, specifically regarding a cylindrical plug welded into a wall. Participants are exploring the approach to determining the stress on the welds as part of a larger school project.

Discussion Character

- Homework-related, Technical explanation

Main Points Raised

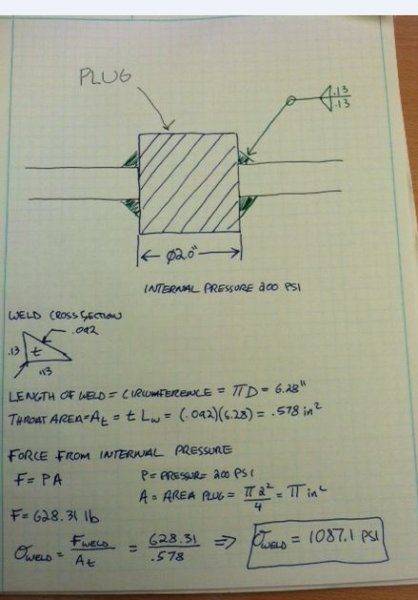

- One participant describes their approach to calculating the stress on the welds and seeks validation of their method.

- Another participant suggests that the calculation of stress in the weld appears to be acceptable.

Areas of Agreement / Disagreement

There is no clear consensus on the correctness of the approach, as only one participant has provided feedback on the calculation without further discussion or challenge.

Contextual Notes

The discussion lacks detailed mathematical steps and specific assumptions that may influence the accuracy of the stress calculation.

Who May Find This Useful

Students and professionals interested in weld stress calculations, pressure vessel design, and related engineering topics may find this discussion relevant.