- #1

Juanda

- 292

- 100

- TL;DR Summary

- Shown welding recommendations seem to contradict Von Mises' failure theory and I don't understand it.

Recently I found these notes with recommendations for welded joints and something is not sitting right with me. It's in Spanish but I'll translate it as close to technical English as I can.

Why is it that triaxial traction causes fragile behavior? I could not find other sources confirming this and explaining the reasons for it.

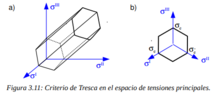

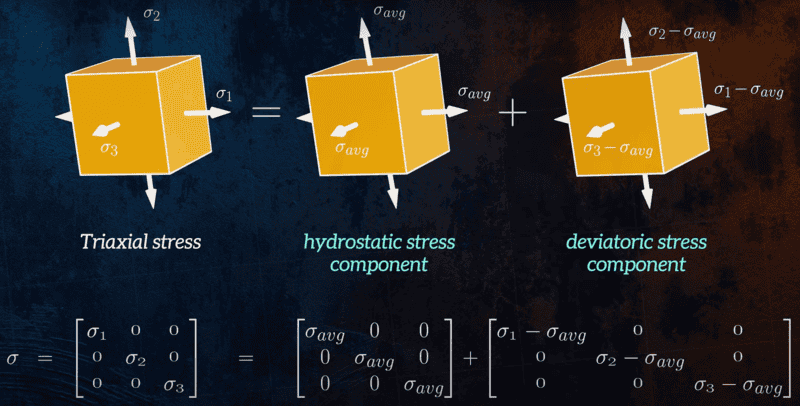

According to Von Mises's failure theory, triaxial traction is easier to withstand than uniaxial traction since its deviatoric stress should be lower even if its hydrostatic component is greater because the last ones do not contribute to failure so I don't understand why the emphasis on this triaxial tension state.

##\sigma_{VM}= \sqrt{\frac{(\sigma_1-\sigma_2)^2+(\sigma_2-\sigma_3)^2+(\sigma_1-\sigma_3)^2}{2}}##

Source:

Does the fabrication process of the 3 cords contacting each other change the chemical properties of the metal so it's no longer ductile? Is it that the high temperatures involved and rapid cooling make it fragile?

I have checked a few sources on the internet and they all say basically the same thing. I couldn't find English sources. Maybe I'm missing the keywords in English. I know these recommendations are used, at least in Spain, because my home university has that kind of joint at the base of the beam pillars. It's a shame I don't have a picture because I've been wondering about this since I was studying there.I'm trying to understand what's the base for these recommendations. I believe the recommendations are related to the thermal expansion of the cords and the residual stress once it cools down. I'm especially troubled with this part of the text "The triaxial traction and its consequent danger of fragile fracture".Translation to English

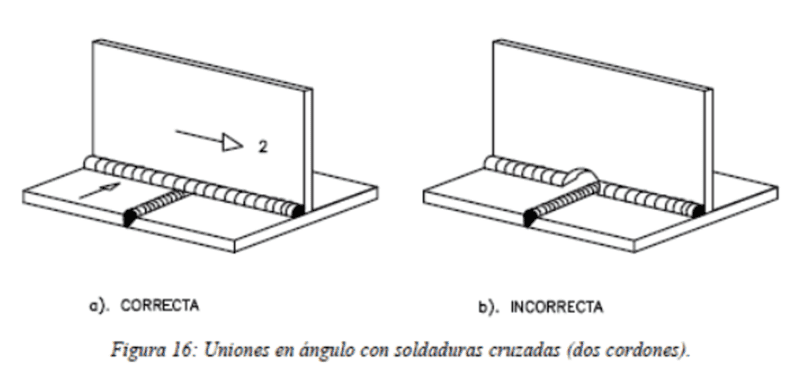

Angled joints with crossed cords

When only 2 cords are crossing (Figure 16) the welds must be done following a), because even if b) avoids biaxial traction, the effect from the hole (entalla) is more negative than the biaxial traction itself.

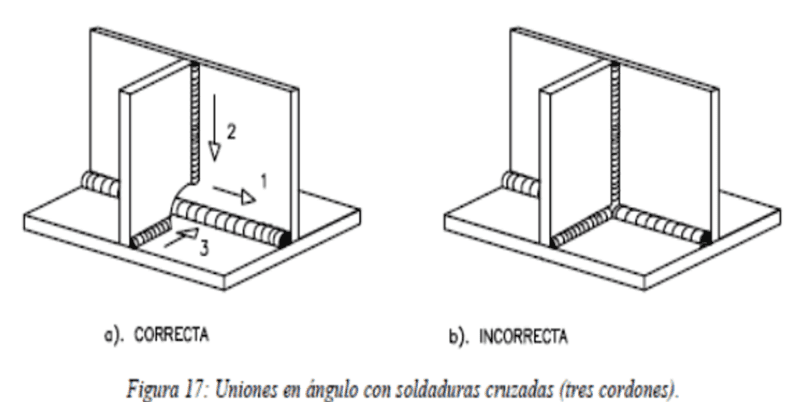

When the joint has 3 cords (Figure 17), the effect from the from the triaxial traction and its consequent danger of fragile fracture implies that the recommended configuration is a) instead of b) although the best possible solution would be to avoid having 3 cords intersecting in a point.

Why is it that triaxial traction causes fragile behavior? I could not find other sources confirming this and explaining the reasons for it.

According to Von Mises's failure theory, triaxial traction is easier to withstand than uniaxial traction since its deviatoric stress should be lower even if its hydrostatic component is greater because the last ones do not contribute to failure so I don't understand why the emphasis on this triaxial tension state.

##\sigma_{VM}= \sqrt{\frac{(\sigma_1-\sigma_2)^2+(\sigma_2-\sigma_3)^2+(\sigma_1-\sigma_3)^2}{2}}##

Source:

Does the fabrication process of the 3 cords contacting each other change the chemical properties of the metal so it's no longer ductile? Is it that the high temperatures involved and rapid cooling make it fragile?