Angus Fergusson

- 2

- 0

- TL;DR

- Modelling a seemingly simple mechanism that is proving to be quite challenging

Hi All,

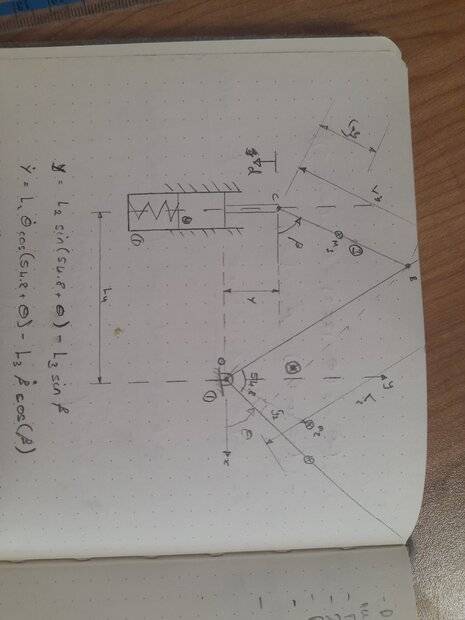

I am trying to model this mechanism for a project. It is a switch that uses a solenoid to break the contact by lifting the aluminium arm. I understand that there is most likely software out there that can do this but i would like to understand how to model this from first principals.

I have got a function for the force on the armature of the solenoid from an electromagnetic modeling software. The force on the armature is the input to the system. I want the motion of the armature, Y, as the output of the model.

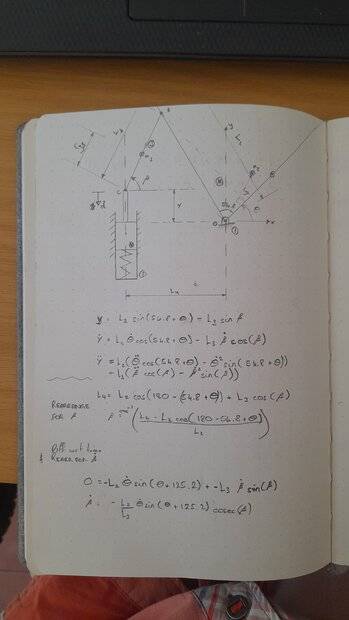

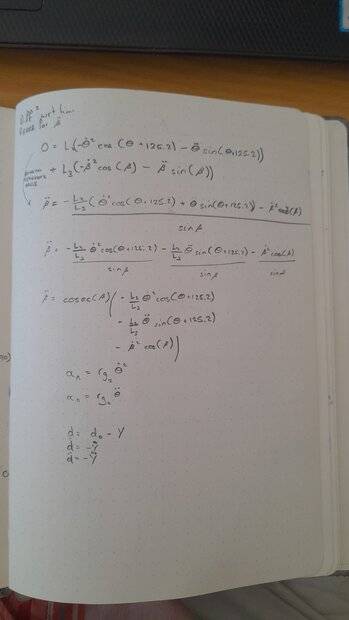

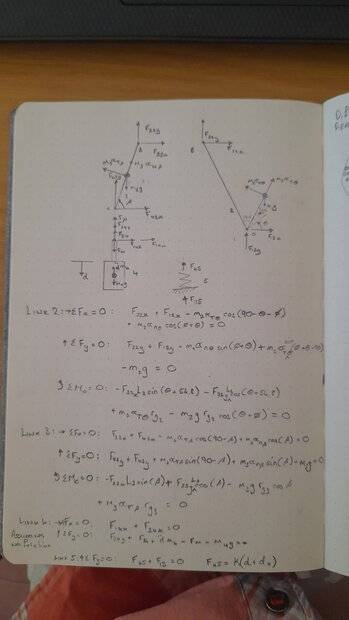

So far I have found Y and its derivatives in terms of theta and beta which are the angle of the link 2 (crank) and the angle of link 3 (con rod), respectively. I have also found beta and its derivatives in terms of theta (meaning that i effectively have Y in terms of theta). After that there is the force balance on each link. I have left friction on the armature out for now, F_mu.

At the moment I am struggling with creating the equations of motion of the armature (Ydotdot = TotalForceOnArmature/MassOfArmature). Any help would be greatly appreciated

Thanks in advance!

I am trying to model this mechanism for a project. It is a switch that uses a solenoid to break the contact by lifting the aluminium arm. I understand that there is most likely software out there that can do this but i would like to understand how to model this from first principals.

I have got a function for the force on the armature of the solenoid from an electromagnetic modeling software. The force on the armature is the input to the system. I want the motion of the armature, Y, as the output of the model.

So far I have found Y and its derivatives in terms of theta and beta which are the angle of the link 2 (crank) and the angle of link 3 (con rod), respectively. I have also found beta and its derivatives in terms of theta (meaning that i effectively have Y in terms of theta). After that there is the force balance on each link. I have left friction on the armature out for now, F_mu.

At the moment I am struggling with creating the equations of motion of the armature (Ydotdot = TotalForceOnArmature/MassOfArmature). Any help would be greatly appreciated

Thanks in advance!