jfoster

- 2

- 0

Hello,

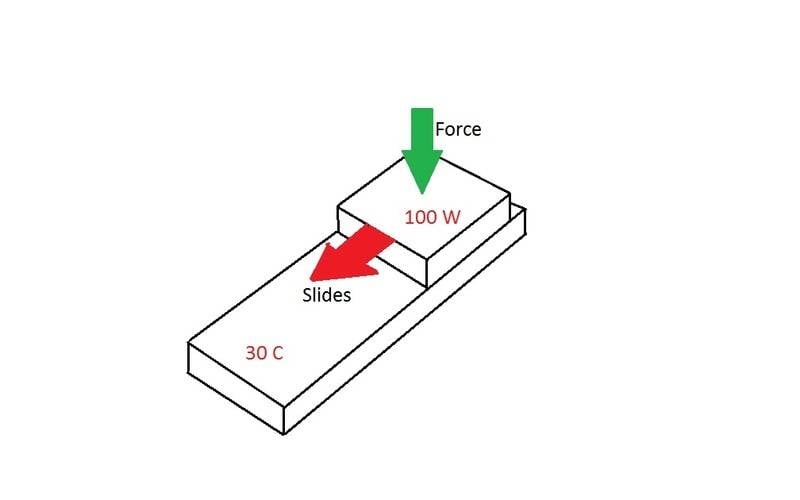

I have a little problem I'm thinking about for work. We are considering a design that moves heat across a contact interface between 2 heat exchangers, each made of copper, in a high vacuum environment. There will be one fixed heat exchanger, maintained at 25 C by coolant flow. This fixed heat exchanger is about 2" x 6" x 1/2" thick. Against this slides a 2" x 2" x 1/2" thick block, which provides a 100W heat load. The smaller block has a lengthwise stroke of about 4". Both contact surfaces can be specified with a very high surface quality, and will be lubed with vacuum grease. The force which holds the two blocks together is up to me. The system needs to be reliable for about 100k cycles or 10 years.

I am just a lowly mechanical engineer, trying to model this system to figure out something about performance. I use COSMOS/works fairly well, but I have no idea how to model this interface with any kind of accuracy. I know that without the grease, no matter how well the surfaces are finished there will be only a few points of contact. In vacuum, there will be no convective heat transfer, so transfer is up to the grease. The problem is, I don't know what the grease will be like in 10 years or if it will have all been scraped off.

I have considered modelling this system in COSMOS/works by putting a thin layer of material (2 thou, or so) between the two blocks which has a thermal conductivity which is less than the published thermal conductivity of the vac grease by a factor of say, 2 - 5, and see what happens... Any better ideas?

MS Paint pic below

I have a little problem I'm thinking about for work. We are considering a design that moves heat across a contact interface between 2 heat exchangers, each made of copper, in a high vacuum environment. There will be one fixed heat exchanger, maintained at 25 C by coolant flow. This fixed heat exchanger is about 2" x 6" x 1/2" thick. Against this slides a 2" x 2" x 1/2" thick block, which provides a 100W heat load. The smaller block has a lengthwise stroke of about 4". Both contact surfaces can be specified with a very high surface quality, and will be lubed with vacuum grease. The force which holds the two blocks together is up to me. The system needs to be reliable for about 100k cycles or 10 years.

I am just a lowly mechanical engineer, trying to model this system to figure out something about performance. I use COSMOS/works fairly well, but I have no idea how to model this interface with any kind of accuracy. I know that without the grease, no matter how well the surfaces are finished there will be only a few points of contact. In vacuum, there will be no convective heat transfer, so transfer is up to the grease. The problem is, I don't know what the grease will be like in 10 years or if it will have all been scraped off.

I have considered modelling this system in COSMOS/works by putting a thin layer of material (2 thou, or so) between the two blocks which has a thermal conductivity which is less than the published thermal conductivity of the vac grease by a factor of say, 2 - 5, and see what happens... Any better ideas?

MS Paint pic below