- #1

FEAnalyst

- 345

- 144

- TL;DR Summary

- How to calculate a temperature at a base surface of a straight fin heat sink?

Hi,

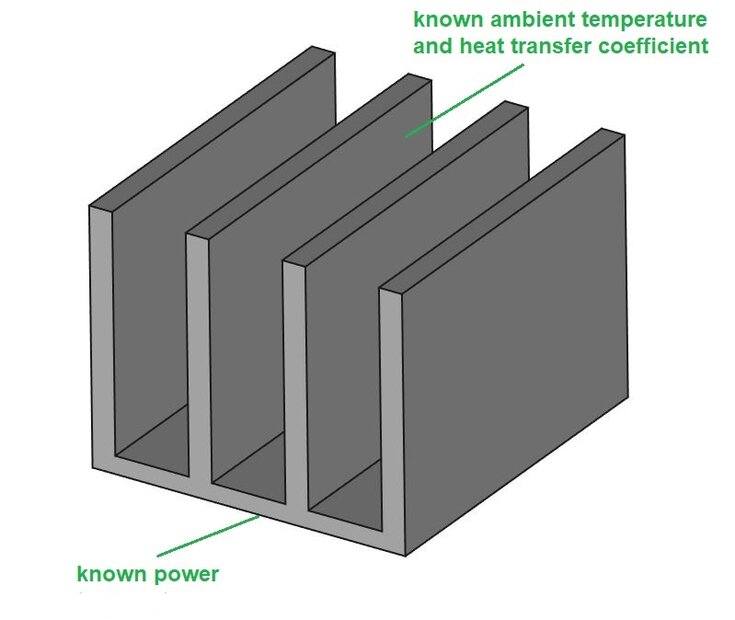

I've checked the literature but couldn't find any formulas or examples for this particular problem involving heat sink with straight fins:

As you can see, I want to assume:

- power at the bottom surface

- convection (known ambient temperature and heat transfer coefficient) at the remaining surfaces

and calculate the temperature at the bottom surface (which should be lower than in the case when the plate has no fins).

All the formulas and examples that I've found are for different boundary conditions - know temperature or convection conditions at the bottom surface and solving for total heat flux. Here are such formulas for the case with the known temperature at the bottom surface (source: old Polish book "Heat transfer and heat exchangers" by Pudlik):

- heat dissipated from each fin: $$Q_{f}=\frac{\alpha U}{m} \cdot \left( T_{s} - T_{a} \right) \cdot tanh(mL)$$ where: ##\alpha## - heat transfer coefficient, ##U## - circumference of the fin's cross-section, ##m=\sqrt{\frac{\alpha U}{\lambda A_{f}}}##, ##T_{s}## - temperature of the bottom surface, ##T_{a}## - ambient temperature, ##\lambda## - thermal conductivity, ##A_{f}## - area of the fin's cross-section.

- heat dissipated from each surface between fins: $$Q_{bf}=\alpha A \cdot \left( T_{s} - T_{a} \right)$$ where: ##A## - area of the surface between fins

- total heat flux: $$Q_{t}=n_{f} \cdot Q_{f}+n_{bf} \cdot Q_{bf}$$ where: ##n_{f}## - number of fins, ##n_{bf}## - number of surfaces between fins

This way it's possible to calculate total heat flux but how can I obtain the temperature at the bottom surface and how to replace the known temperature of the bottom surface with the known power ? Do you think that the formulas above account for all the surfaces involved in convection (all the existing surfaces apart from the bottom one) or some are omitted ?

I've checked the literature but couldn't find any formulas or examples for this particular problem involving heat sink with straight fins:

As you can see, I want to assume:

- power at the bottom surface

- convection (known ambient temperature and heat transfer coefficient) at the remaining surfaces

and calculate the temperature at the bottom surface (which should be lower than in the case when the plate has no fins).

All the formulas and examples that I've found are for different boundary conditions - know temperature or convection conditions at the bottom surface and solving for total heat flux. Here are such formulas for the case with the known temperature at the bottom surface (source: old Polish book "Heat transfer and heat exchangers" by Pudlik):

- heat dissipated from each fin: $$Q_{f}=\frac{\alpha U}{m} \cdot \left( T_{s} - T_{a} \right) \cdot tanh(mL)$$ where: ##\alpha## - heat transfer coefficient, ##U## - circumference of the fin's cross-section, ##m=\sqrt{\frac{\alpha U}{\lambda A_{f}}}##, ##T_{s}## - temperature of the bottom surface, ##T_{a}## - ambient temperature, ##\lambda## - thermal conductivity, ##A_{f}## - area of the fin's cross-section.

- heat dissipated from each surface between fins: $$Q_{bf}=\alpha A \cdot \left( T_{s} - T_{a} \right)$$ where: ##A## - area of the surface between fins

- total heat flux: $$Q_{t}=n_{f} \cdot Q_{f}+n_{bf} \cdot Q_{bf}$$ where: ##n_{f}## - number of fins, ##n_{bf}## - number of surfaces between fins

This way it's possible to calculate total heat flux but how can I obtain the temperature at the bottom surface and how to replace the known temperature of the bottom surface with the known power ? Do you think that the formulas above account for all the surfaces involved in convection (all the existing surfaces apart from the bottom one) or some are omitted ?