abdulbadii

- 43

- 1

- TL;DR

- Understand to solve 3.17 mm d. shaft function as 5 mm one

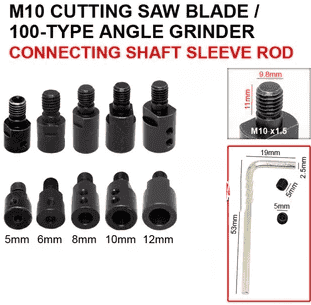

Anyone understand to do as correctly as possible on 3.17 mm d. shaft function as 5 mm one, as the available affordable is motor shaft 3.17 mm diameter and the (leftmost image of adv.) connector/adapter of 5 mm diameter M10 ?

So what'd be the most suitable pad/filler and how is to do it?

So what'd be the most suitable pad/filler and how is to do it?

Last edited: