DefinitelyAnEnjinear

- 10

- 6

- TL;DR

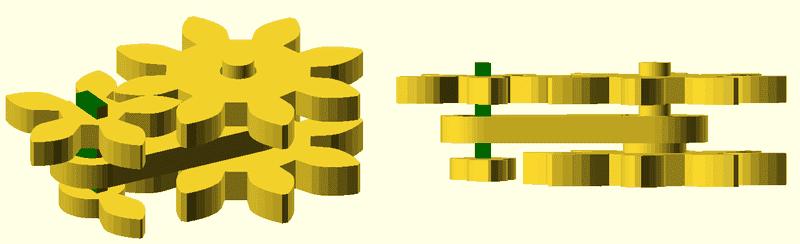

- I designed a weird geneva mechanism where the driving pin is mounted on the geneva wheel and pushes against gear fixed to the central axis to rotate the geneva wheel.

Two things that I think I should say before I describe what I did: First, I do not have any physics-related background (but I have a degree in CS, and I'd like to think I have a good enough grasp on math to be able to understand equations describing motion of objects). So please forgive me if I'm missing things that may seem obvious to you.

Second, there's a (good, in my opinion) reason why I went for this approach rather than just using a normal geneva mechanism, which will be explained in part 2.

And in action:

here it is working!

and here it is, without cheating, not working as intended.

The idea is that what would've been the driving pin in a normal geneva mechanism (here, a gear with only 1 of its teeth, located at the bottom) pushes against a gear that doesn't rotate, mounted on the central axis, and causes the thing it's mounted on to rotate.

when I drive the thing with my hand, it works fine. but when I place the gear that's supposed to drive the whole thing on the center axis, it either jams when the single tooth at the bottom engages with the gear at the bottom,or it simply gets dragged along with the big gear (as @Baluncore pointed out, I did not include a locking mechanism - I never understood why it's needed in normal geneva mechanisms, so I've learned to ignore it, but clearly it's needed here) (the jamming is harder for me to understand, the dragging along isn't much of a mystery to me).

This is all for a toy - it's not going to be subjected to any serious stress, there is no cost if it breaks, no maintenance... It's just something designed for fun by someone who barely knows what he's doing.

What is important to me is using a minimal number of parts however, and this approach makes it easier because of what I'm going to use it for:

I have these 8 knobs (each attached to a stick; not depicted). I need a mechanism to engage with each one, push it away, then pull it back in, and then disengage with the knob before moving on to the next one.

My simpler idea was to use a very simple cam to guide each of those

Imagine the blue circle is centered, the black lines inside the square are the cam, the red arrows depict the direction the cam is supposed to push the knobs as the cam rotates around the blue circle. I hope you have a vivid imagination because I'm not great at drawing.

However that didn't work out because the cam applied too much force on the knobs to the side rather than forward/backward, and I would have to make the whole thing a lot bigger to make it work, as far as I can tell.

So instead I had the idea of making this weird geneva mechanism, figuring the smaller gear (the one not missing teeth) could double as a cam for a mechanism (to be added later), and I could use its rotation (minus the part where the bottom, lone tooth engages with the bottom gear) to move another cam-and-follower mechanism that will push and then pull the knob.

in addition to having a fewer number of parts, I figured that (assuming I have no choice but to have a cam-and-follower mechanism orbiting around to engage with each knob) I would have no choice but to have a rotating gear at the center of the circle (only place to put a gear to ensure it's always in contact with another gear orbiting the center), so rather than driving the geneva mechanism and the orbiting cam-and-follower with 2 gears, I could combine it and make the whole arrangement of what I'm designing easier.

After a few failed attempts, I am here asking for your help (and forgiveness for any sins I may have committed against engineering)

Second, there's a (good, in my opinion) reason why I went for this approach rather than just using a normal geneva mechanism, which will be explained in part 2.

Part 1: What I'm going for

The parts I designed, rendered:And in action:

here it is working!

and here it is, without cheating, not working as intended.

The idea is that what would've been the driving pin in a normal geneva mechanism (here, a gear with only 1 of its teeth, located at the bottom) pushes against a gear that doesn't rotate, mounted on the central axis, and causes the thing it's mounted on to rotate.

when I drive the thing with my hand, it works fine. but when I place the gear that's supposed to drive the whole thing on the center axis, it either jams when the single tooth at the bottom engages with the gear at the bottom,

Part 2: Why not use a normal geneva mehanism?

I think this can be boiled down to my set of priorities.This is all for a toy - it's not going to be subjected to any serious stress, there is no cost if it breaks, no maintenance... It's just something designed for fun by someone who barely knows what he's doing.

What is important to me is using a minimal number of parts however, and this approach makes it easier because of what I'm going to use it for:

I have these 8 knobs (each attached to a stick; not depicted). I need a mechanism to engage with each one, push it away, then pull it back in, and then disengage with the knob before moving on to the next one.

My simpler idea was to use a very simple cam to guide each of those

Imagine the blue circle is centered, the black lines inside the square are the cam, the red arrows depict the direction the cam is supposed to push the knobs as the cam rotates around the blue circle. I hope you have a vivid imagination because I'm not great at drawing.

However that didn't work out because the cam applied too much force on the knobs to the side rather than forward/backward, and I would have to make the whole thing a lot bigger to make it work, as far as I can tell.

So instead I had the idea of making this weird geneva mechanism, figuring the smaller gear (the one not missing teeth) could double as a cam for a mechanism (to be added later), and I could use its rotation (minus the part where the bottom, lone tooth engages with the bottom gear) to move another cam-and-follower mechanism that will push and then pull the knob.

in addition to having a fewer number of parts, I figured that (assuming I have no choice but to have a cam-and-follower mechanism orbiting around to engage with each knob) I would have no choice but to have a rotating gear at the center of the circle (only place to put a gear to ensure it's always in contact with another gear orbiting the center), so rather than driving the geneva mechanism and the orbiting cam-and-follower with 2 gears, I could combine it and make the whole arrangement of what I'm designing easier.

After a few failed attempts, I am here asking for your help (and forgiveness for any sins I may have committed against engineering)

Last edited: