Arnsol

- 2

- 0

- Homework Statement

- w

- Relevant Equations

- See attepmt

Hello,

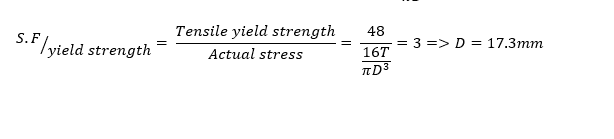

So we are designing a turbine. We have a shaft that receives 710W / 13.6NM / 500RPM from the runner and we are going to find a diameter with safety factor of 3.

Take the following information regarding metal:

Aluminium 6061

i know F.O.S = Max load / Load applied.

Still i can't wrap my mind around which of those i should use. First thought is going with the 48 MPA yield since aluminium is ductile?

Any thoughts? I am so confused...

So we are designing a turbine. We have a shaft that receives 710W / 13.6NM / 500RPM from the runner and we are going to find a diameter with safety factor of 3.

Take the following information regarding metal:

Aluminium 6061

| Tensile strength | 115 MPa | |

| Yield strength | 48 MPa | |

| Shear strength | 83 MPa | |

| Fatigue strength | 62 MPa |

Still i can't wrap my mind around which of those i should use. First thought is going with the 48 MPA yield since aluminium is ductile?

Any thoughts? I am so confused...