Catusee

- 2

- 0

Summary:: I want to design a mechanism consisting in 4 rack driven pinions , like an elevator and i need help in choosing the right motor.

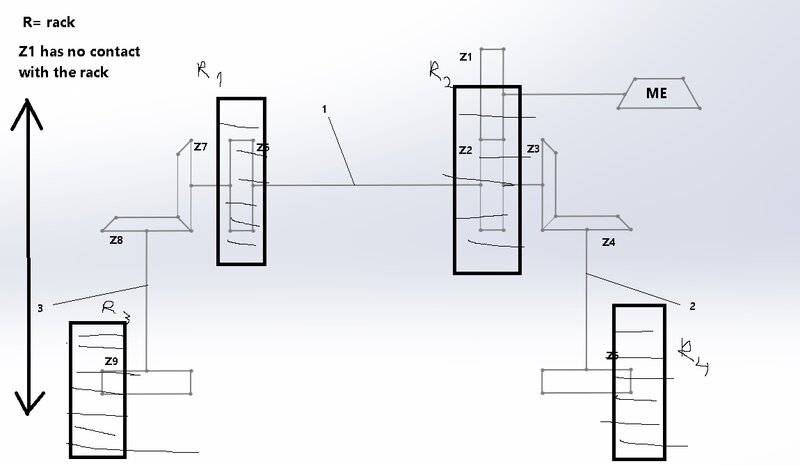

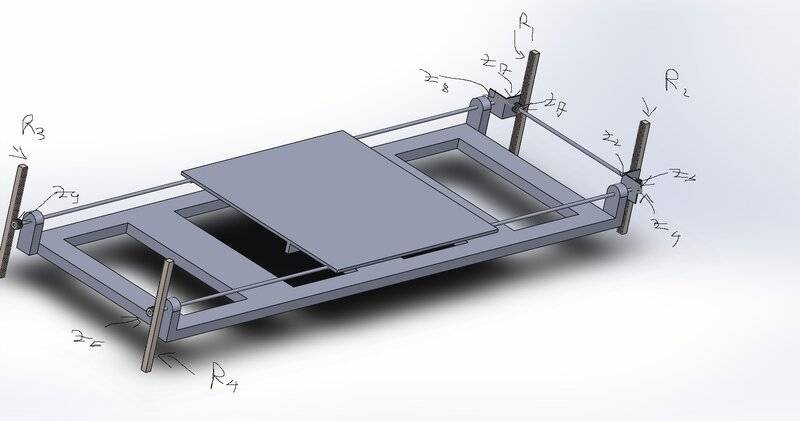

Hello!I want to design a mechanism consisting in 4 rack driven pinions , connected to each other via shafts, used for a positioning system , a moving up and down platform. It has to carry a load of 1.5 kg and has a speed of 0.036m/s.(the length of the rack is 110 mm(module 0.4) and the platform has to go from the bottom of the rack to the top in 3 seconds).The motor has to hold the whole load when the mechanism stops , it has to have a break.I need help in calculating the parameters of the required motor .Thank you for your time !

The gears atatched to the racks are spur gears , module 0.4 with 20 teeth and the gears connecting the shafts are miter gears with module 0.5 , 20 teeth.

Mentor note: Moved from Mechanical Engineering forum, so no template.

Hello!I want to design a mechanism consisting in 4 rack driven pinions , connected to each other via shafts, used for a positioning system , a moving up and down platform. It has to carry a load of 1.5 kg and has a speed of 0.036m/s.(the length of the rack is 110 mm(module 0.4) and the platform has to go from the bottom of the rack to the top in 3 seconds).The motor has to hold the whole load when the mechanism stops , it has to have a break.I need help in calculating the parameters of the required motor .Thank you for your time !

The gears atatched to the racks are spur gears , module 0.4 with 20 teeth and the gears connecting the shafts are miter gears with module 0.5 , 20 teeth.

Mentor note: Moved from Mechanical Engineering forum, so no template.

Last edited by a moderator: