- #1

Will_SPHS

- 18

- 4

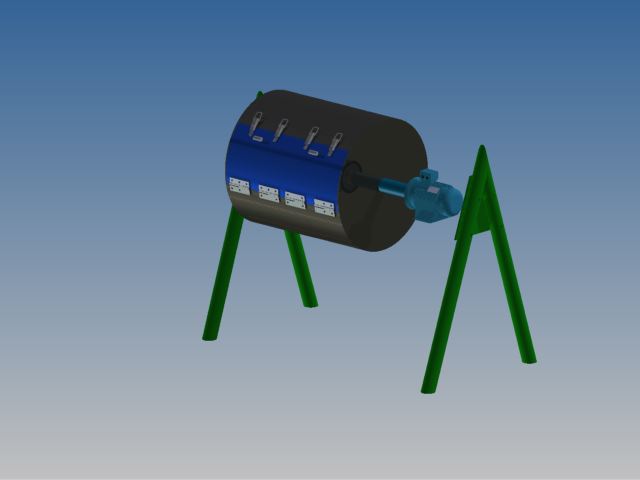

I am working on a school project where a motor needs to turn a drum. The motor is mounted to one side of the drum.

The motor is much smaller than the one in the picture, and won't be able to attach directly to the axle. Currently, I am thinking that I attach a pinion to the end of the motor shaft and attach a larger gear on the side of the drum to rotate it. The motor will then be offset by the respective center distance.

The maximum required balancing torque for the drum is 8.35 lb*ft. The motor we are using provides 7.8 lbft at 2 rpm. The output rpm of the second gear isn't a big deal. It can be anything, but for simplicity's sake, I will make it 1 rpm. That means the gear ratio of the two gear system is 2.

I need to make the gear system in Inventor so that I can attach it to the 3D model. I know that I need to go to the Design tab -> Power Transmission -> Spur Gear in order to make the system, but am otherwise lost. It is asking for diametral pitch and some other things that I have no idea how to figure out. My question is, how exactly do I create the specified gear system in Inventor?

Thank you!

Other information:

[ mentor note: image fixed ]

The motor is much smaller than the one in the picture, and won't be able to attach directly to the axle. Currently, I am thinking that I attach a pinion to the end of the motor shaft and attach a larger gear on the side of the drum to rotate it. The motor will then be offset by the respective center distance.

The maximum required balancing torque for the drum is 8.35 lb*ft. The motor we are using provides 7.8 lbft at 2 rpm. The output rpm of the second gear isn't a big deal. It can be anything, but for simplicity's sake, I will make it 1 rpm. That means the gear ratio of the two gear system is 2.

I need to make the gear system in Inventor so that I can attach it to the 3D model. I know that I need to go to the Design tab -> Power Transmission -> Spur Gear in order to make the system, but am otherwise lost. It is asking for diametral pitch and some other things that I have no idea how to figure out. My question is, how exactly do I create the specified gear system in Inventor?

Thank you!

Other information:

- The motor shaft size is 6mm (0.236'').

- The drum diameter is 1'. The gear system needs to take up less than this diameter so that it can be covered by an end cap of the same diameter as the drum.

[ mentor note: image fixed ]

Last edited by a moderator: