dbeckam

- 8

- 1

- TL;DR

- Find the rotation matrix

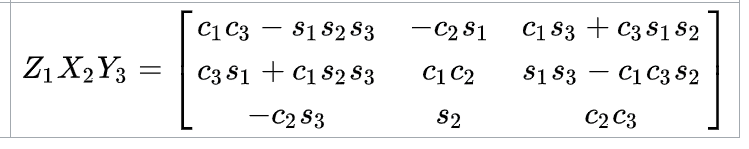

I have three frames. The first is the fixed global frame. the second rotates an angle PHIZ with respect to the first. And the third first rotates a PHIX angle with respect to the x axis of the second frame, and then rotates a PHIY angle with respect to the last y axis. That is, there are a total of three intrinsic rotations Z, X, Y. According to Wikipedia, the final rotation matrix results from the image. I would appreciate if you could help me verify two things:

1) The angular velocity of the rotation matrix. According to my calculations the result is:

wpx=dphix.*cos(phiz)-dphiy.*cos(phix).*sin(phiz);

wpy=dphix.*sin(phiz)+dphiy.*cos(phix).*cos(phiz);

wpz=dphiz+dphiy.*sin(phix);

2) If I put an IMU sensor in the last frame, it measures the angles in a different format: yaw, pitch, and roll rotations. How can I use these angles to get my initial PHIZ, PHIX and PHIY angles?

1) The angular velocity of the rotation matrix. According to my calculations the result is:

wpx=dphix.*cos(phiz)-dphiy.*cos(phix).*sin(phiz);

wpy=dphix.*sin(phiz)+dphiy.*cos(phix).*cos(phiz);

wpz=dphiz+dphiy.*sin(phix);

2) If I put an IMU sensor in the last frame, it measures the angles in a different format: yaw, pitch, and roll rotations. How can I use these angles to get my initial PHIZ, PHIX and PHIY angles?