Lluis

- 4

- 0

- TL;DR

- How to change Scotch yoke mechanism parameters in order to calculate slider movement

Hi,

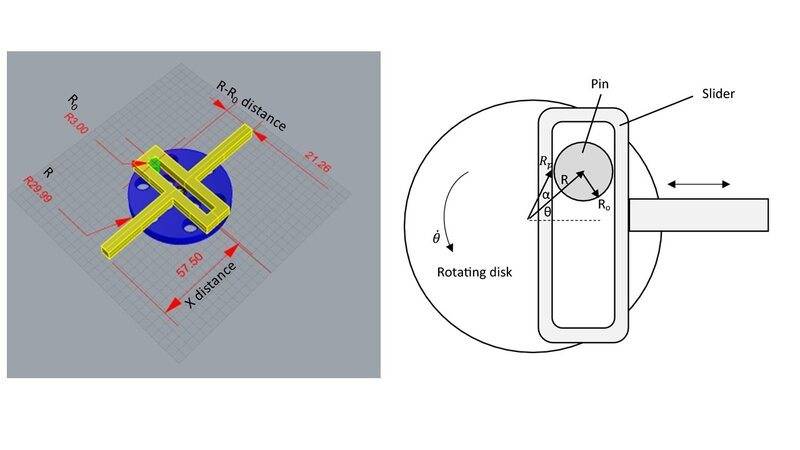

I am not an engineer and sorry in advance if I am not correct with the terms. I design out of curiosity this Scotch yoke mechanism (left image) based on a scheme (right image).

I looked for some equations to find if there is a relation between the R0 , R to R0 distance (which changes during rotation) and the X distance. If for example, I will change the parameters R0 , R to R0 distance and the slider horizontal part/s length/s how it will effect the X distance movement?

Any idea how to calculate it?

Thanks a lot.

I am not an engineer and sorry in advance if I am not correct with the terms. I design out of curiosity this Scotch yoke mechanism (left image) based on a scheme (right image).

I looked for some equations to find if there is a relation between the R0 , R to R0 distance (which changes during rotation) and the X distance. If for example, I will change the parameters R0 , R to R0 distance and the slider horizontal part/s length/s how it will effect the X distance movement?

Any idea how to calculate it?

Thanks a lot.