- #1

howardt0818

- 9

- 0

- TL;DR Summary

- I am trying to calculate the required Torque to drive an object at a given speed.

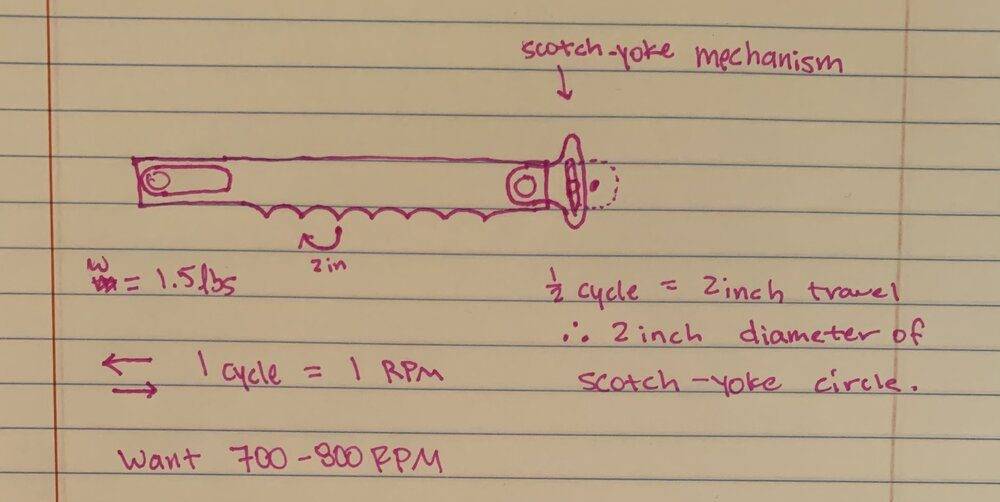

I am designing a reciprocating saw that I plan to use a scotch-yoke mechanism to convert rotational kinetic energy into linear kinetic energy.

I want to spec out a motor and the final thing I need to calculate is the required torque. The motor must be 12 Volts and I need to know the required torque so I can purchase a motor.

Saw blade weight: 1.5 lbs

Desired cut travel: 2 inches

Desired RPM: 800 RPM

To achieve a cut travel of 2 inches, the scotch yoke circle that will be attached directly to the motor must be 2 inches in diameter.

What equation could I use to calculate this?

Power and current can be altered to achieve this but the voltage will be operating at 12V and the motor will be DC geared most-likely.

I want to spec out a motor and the final thing I need to calculate is the required torque. The motor must be 12 Volts and I need to know the required torque so I can purchase a motor.

Saw blade weight: 1.5 lbs

Desired cut travel: 2 inches

Desired RPM: 800 RPM

To achieve a cut travel of 2 inches, the scotch yoke circle that will be attached directly to the motor must be 2 inches in diameter.

What equation could I use to calculate this?

Power and current can be altered to achieve this but the voltage will be operating at 12V and the motor will be DC geared most-likely.