SUMMARY

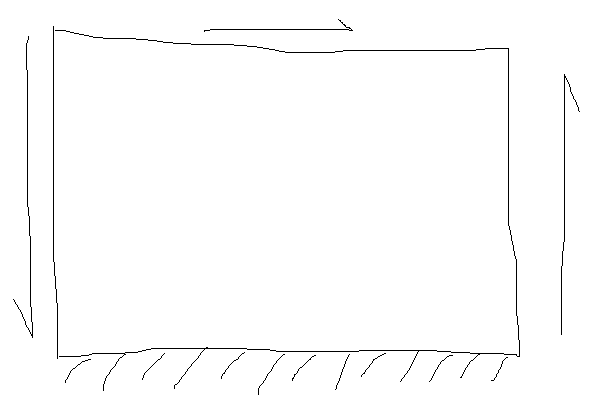

The discussion focuses on the phenomenon of stress and strain concentration in a rectangle subjected to pure shear loading, specifically when modeled using Finite Element Analysis (FEA). Despite the expectation of uniform deformation, the FEA results indicate stress concentrations at the bottom corners, which are identified as singularities. The participants question the presence of these singularities, noting that the fixed boundary condition at the bottom should not differentiate these corners from the other vertices. Understanding these singularities is crucial for accurate modeling and analysis in structural engineering.

PREREQUISITES

- Finite Element Analysis (FEA) principles

- Understanding of shear loading and its effects on materials

- Knowledge of boundary conditions in FEA simulations

- Concept of stress and strain singularities in structural analysis

NEXT STEPS

- Investigate methods to mitigate stress singularities in FEA models

- Learn about advanced meshing techniques in FEA to improve accuracy

- Explore the impact of boundary conditions on stress distribution in FEA

- Study the theory of elasticity related to shear loading scenarios

USEFUL FOR

Structural engineers, FEA analysts, and researchers focused on material behavior under shear loading conditions will benefit from this discussion.