- #1

- 11,308

- 8,732

I'm curious about this failure mode.

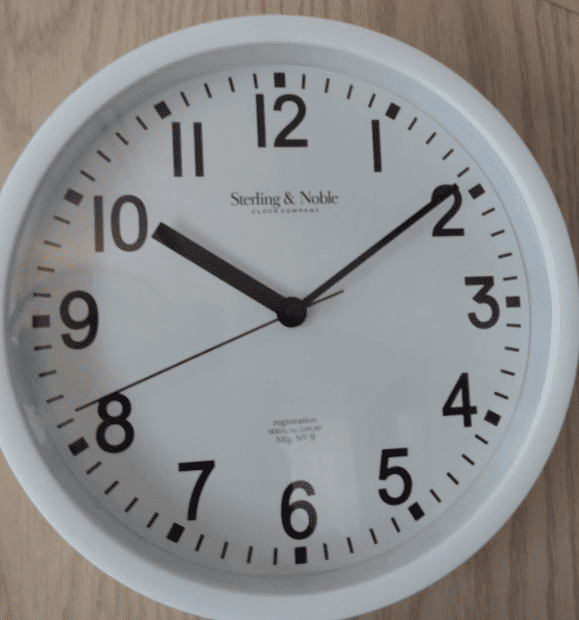

I had a cheap ($3.82) wall clock from 2017. On Tuesday, it stopped working, getting stuck at the 41 seconds position. The second hand twitches every 1 second, but it does not advance. Since it was so cheap, I threw it away and bought a new one (also $3.82). The new one claims to be a different brand, but it failed in less than 1 hour use.

The new clock with a new battery, also fails the same way and also at the 41 second position. Actually, it stuck once at 49 seconds, but a dozen or more times at the 41 second mark. If I lay it down horizontally on a table, it keeps good time and doesn't get stuck.

I could spend $382.00 for a clock, but the money could go to cosmetics. Worse, it might have the identical quartz movement with a single AA battery. That movement seems ubiquitous in recent years. I've seen it in many brands of clocks.

Do those movements use stepper motors? Aside from the fact that 31-59 seconds is lifts the second hand and thus uses more torque, is there any good reason for random failures to result in such exact symptoms?

If the clock movement has injection molded plastic gears, there may be a remnant of the parting-line/sprue/gate- marks/ejector-pin-marks in the same place on both the old and new gears. That would make it a common mode failure.

Any more speculations?

I had a cheap ($3.82) wall clock from 2017. On Tuesday, it stopped working, getting stuck at the 41 seconds position. The second hand twitches every 1 second, but it does not advance. Since it was so cheap, I threw it away and bought a new one (also $3.82). The new one claims to be a different brand, but it failed in less than 1 hour use.

The new clock with a new battery, also fails the same way and also at the 41 second position. Actually, it stuck once at 49 seconds, but a dozen or more times at the 41 second mark. If I lay it down horizontally on a table, it keeps good time and doesn't get stuck.

I could spend $382.00 for a clock, but the money could go to cosmetics. Worse, it might have the identical quartz movement with a single AA battery. That movement seems ubiquitous in recent years. I've seen it in many brands of clocks.

Do those movements use stepper motors? Aside from the fact that 31-59 seconds is lifts the second hand and thus uses more torque, is there any good reason for random failures to result in such exact symptoms?

If the clock movement has injection molded plastic gears, there may be a remnant of the parting-line/sprue/gate- marks/ejector-pin-marks in the same place on both the old and new gears. That would make it a common mode failure.

Any more speculations?