- #1

amare

- 18

- 2

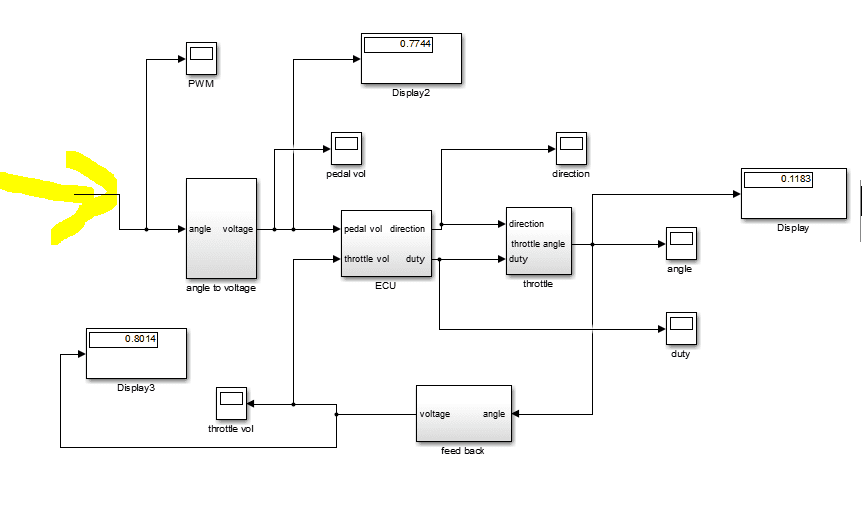

I modeled a throttle body in Simulink. How do I model the position of the gas pedal so that if the position of the gas pedal changes the input voltage to the throttle body actuator will change and open the throttle? why should i give on the left side to get position of the gas pedal from the potentiometer sensor?