- #1

Saints-94

- 63

- 1

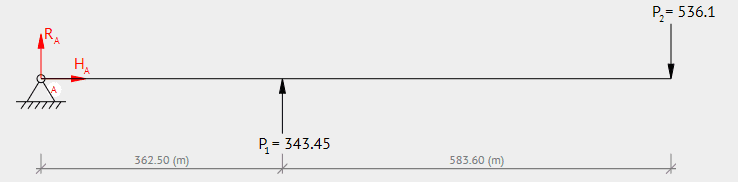

I have ran an FEA simulation on a lever to work out the stress on the part. I have now started doing some hand calculations to validate the software results and am struggling to get the values to match up. I am unsure whether my calculations are wrong, or whether the software is incorrect.

The part is a metal tube (below), with a 25.3mm diameter and 2mm wall thickness.

I know that;

Stress = My / I

I have worked my bending moment out as

M(x1) = + RA*(x1) - MA

M1(0) = + 192.65*(0) - 382703.59 = -382703.59 (N*m)

M1(362.50) = + 192.65*(362.50) - 382703.59 = -312867.96 (N*m)

Y= D/2

=12.65mm = 0.01265m

I = (pi * D^4) / 64

= (pi/64) * (0.0253^4 - 0.0233^4)

The answer I have calculated is 7.05 x 10^11 Nm2

and FEA analysis = 2.1 x 10^8 Nm2

Please come someone confirm whether my hand calcs are correct or not?

The part is a metal tube (below), with a 25.3mm diameter and 2mm wall thickness.

I know that;

Stress = My / I

I have worked my bending moment out as

M(x1) = + RA*(x1) - MA

M1(0) = + 192.65*(0) - 382703.59 = -382703.59 (N*m)

M1(362.50) = + 192.65*(362.50) - 382703.59 = -312867.96 (N*m)

Y= D/2

=12.65mm = 0.01265m

I = (pi * D^4) / 64

= (pi/64) * (0.0253^4 - 0.0233^4)

The answer I have calculated is 7.05 x 10^11 Nm2

and FEA analysis = 2.1 x 10^8 Nm2

Please come someone confirm whether my hand calcs are correct or not?