Discussion Overview

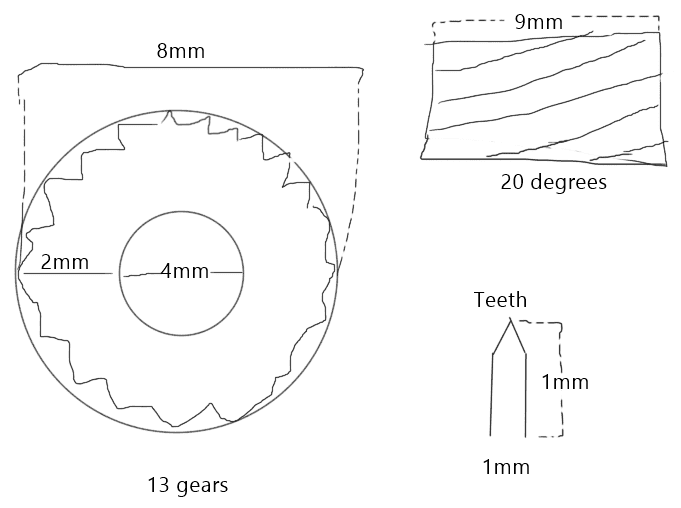

The discussion revolves around finding replacement pinion gears for a microscope, specifically a broken helical pinion gear. Participants explore options for sourcing replacements, including standard sizes, 3D printing, and alternative methods for creating or adapting gears. The conversation includes technical details about the gear's dimensions and its role in the microscope's focusing mechanism.

Discussion Character

- Exploratory

- Technical explanation

- Debate/contested

- Experimental/applied

Main Points Raised

- One participant inquires about standard sizes for pinion gears and expresses difficulty in finding replacements online.

- Another suggests the gear may be a "screw gear" rather than a pinion gear, despite its function as one.

- Participants discuss the possibility of using modeling clay to create a mold for casting a new gear.

- Several participants request additional details about the microscope's make and model, as well as images of the gear and its surrounding structure.

- One participant identifies the brand as HOC and later clarifies it is a vintage Japanese Y.K.S HOC microscope, expressing doubt about finding spare parts.

- There are suggestions for using a brass cylinder to create a new gear, including techniques for shaping the teeth and ensuring proper fit.

- Some participants discuss the possibility of reattaching the broken gear with super glue, while one mentions that previous attempts have failed.

- Another participant offers a metal gear from their collection but notes it is not suitable due to being right-handed when a left-handed gear is needed.

- One participant advises against making a one-off gear due to potential costs and suggests looking for similar models that may be available cheaply.

Areas of Agreement / Disagreement

Participants express various opinions on the best approach to finding or creating a replacement gear, with no consensus reached on a definitive solution. Some ideas are supported by multiple participants, while others remain contested.

Contextual Notes

Participants mention limitations related to the availability of specific gear types and the challenges of creating a custom gear, including material choices and the feasibility of 3D printing.

Who May Find This Useful

Individuals interested in microscope repairs, hobbyists in mechanical engineering, and those exploring DIY solutions for small mechanical parts may find this discussion relevant.