- 12,178

- 186

I'm trying to understand just how the electric brake on my 24 Vdc lawnmower works.

First, here is the circuit schematic:

For the purposes of this discussion just note that, when the motor is shut off, the motor gets "shorted" when the main switch moves to the OFF/BRAKE position.

Now, I understand that:

1. The short allows an induced current to flow in the motor coils as they spin past the magnets, and

2. The magnetic force on the current-carrying wires will oppose the direction of spin, bringing the motor to a stop.

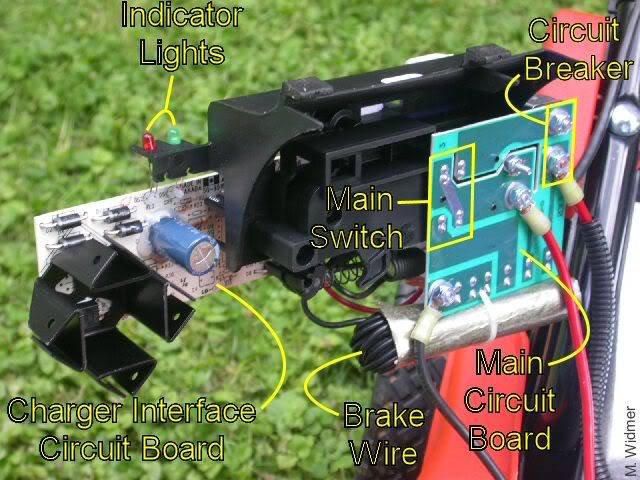

However ... the construction of this thing isn't really a simple short. Instead, it is a 12-foot long, AWG 18 wire coiled in a loop. It is the wire labeled "Brake Wire" in this photo:

So my question is, why is a 12 foot wire needed for this? I estimate it's resistance to be about 0.07 Ω. (12 feet of AWG 18 wire). I assume it's coiled just to fit it into a small space, but of course this would mean a small amount of inductance which may or may not be relevant.

Other details: the motor runs on 24 V DC. [STRIKE]I don't know the current, but there is a 40A circuit breaker, so somewhere between 10 A and 30 A?[/STRIKE] (EDIT 2/26/10: I have measured 12A current on a fully charged battery.)

Also, I'm just assuming it's a permanent magnet motor, but am not 100% on that. It could be a universal motor I suppose.

Thanks in advance!

First, here is the circuit schematic:

For the purposes of this discussion just note that, when the motor is shut off, the motor gets "shorted" when the main switch moves to the OFF/BRAKE position.

Now, I understand that:

1. The short allows an induced current to flow in the motor coils as they spin past the magnets, and

2. The magnetic force on the current-carrying wires will oppose the direction of spin, bringing the motor to a stop.

However ... the construction of this thing isn't really a simple short. Instead, it is a 12-foot long, AWG 18 wire coiled in a loop. It is the wire labeled "Brake Wire" in this photo:

So my question is, why is a 12 foot wire needed for this? I estimate it's resistance to be about 0.07 Ω. (12 feet of AWG 18 wire). I assume it's coiled just to fit it into a small space, but of course this would mean a small amount of inductance which may or may not be relevant.

Other details: the motor runs on 24 V DC. [STRIKE]I don't know the current, but there is a 40A circuit breaker, so somewhere between 10 A and 30 A?[/STRIKE] (EDIT 2/26/10: I have measured 12A current on a fully charged battery.)

Also, I'm just assuming it's a permanent magnet motor, but am not 100% on that. It could be a universal motor I suppose.

Thanks in advance!

Last edited: