- #1

Good4you

- 37

- 0

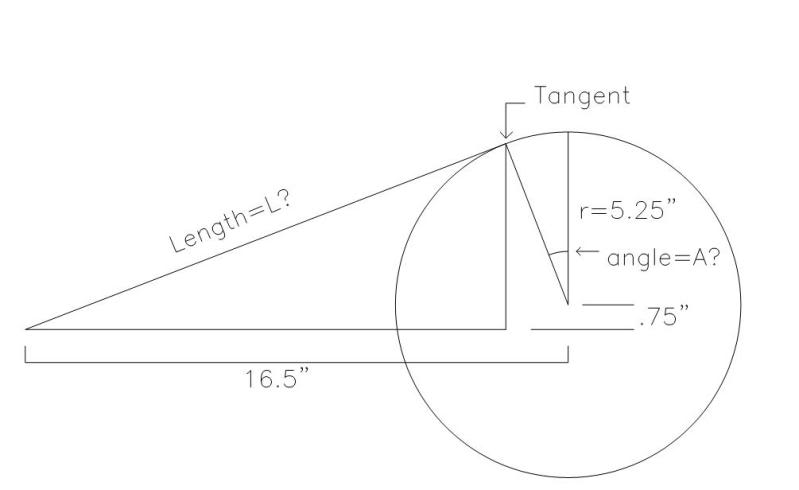

I guess it has been too long since i have had to use any math beyond arithmetic. I am working on fabricating some tube work, and these similar shapes keep coming up. I keep thinking i can calculate them out, but for some reason i always get stumped and feel like i am missing some information. I know this should be easy and the information must be there because i can draw the darn thing in cad. But when working in the garage i do not always have access to a computer, and would like to be able to do these calculations with just a calculator.

Can someone help me find the length, and angle below.

Can someone help me find the length, and angle below.