- #1

tomtomtom1

- 160

- 8

- TL;DR Summary

- Calculating Bending Stress Of A Member

Hello all

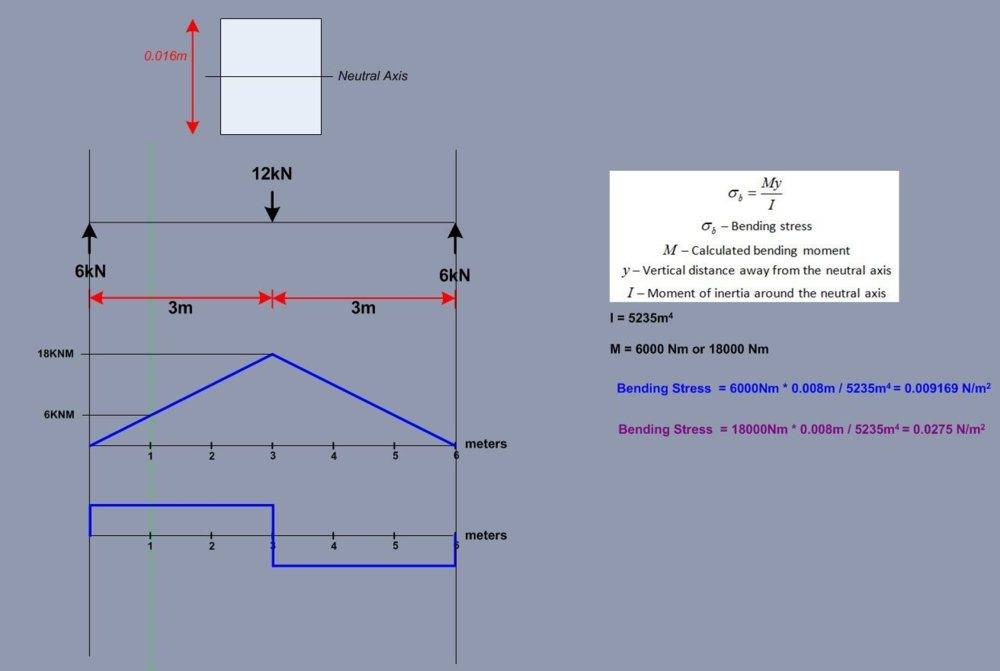

I am trying to calculate the bending stress of a simply supported beam with a load of 12kn at the middle of a 6m span, member depth of 0.016m

I have drawn both the bending moment and shear force diagram.

I want to know the following:-

1) When calculating the bending stress would you always use the Max bending moment Or would you use the bending moment at a particular point along the member? below is a sketch:-

As you can see i have calculated the bending stress at 1m along the beam - is it convention to always use the max bending moment at all points along the beam or the actual bending moment at the point along the beam to which your calculating the bending stress for?

As you can see i have 2 answers and i am not sure which is correct?

2) How would you know that the value i get for bending stress is compressive or tensile, i think that i get a positive value which is compressive because i went 0.008m UP my neutral axis which is in compression - would this be correct?

Thank you.

I am trying to calculate the bending stress of a simply supported beam with a load of 12kn at the middle of a 6m span, member depth of 0.016m

I have drawn both the bending moment and shear force diagram.

I want to know the following:-

1) When calculating the bending stress would you always use the Max bending moment Or would you use the bending moment at a particular point along the member? below is a sketch:-

As you can see i have calculated the bending stress at 1m along the beam - is it convention to always use the max bending moment at all points along the beam or the actual bending moment at the point along the beam to which your calculating the bending stress for?

As you can see i have 2 answers and i am not sure which is correct?

2) How would you know that the value i get for bending stress is compressive or tensile, i think that i get a positive value which is compressive because i went 0.008m UP my neutral axis which is in compression - would this be correct?

Thank you.