- #1

karabiner98k

- 90

- 12

We all know that torque consists of force and distance. If we apply torque to the center of a car wheel, the force that the tire exerts to the ground can be calculated by dividing the torque by tire radius but what about applying torque to one of lug nuts which is off center?

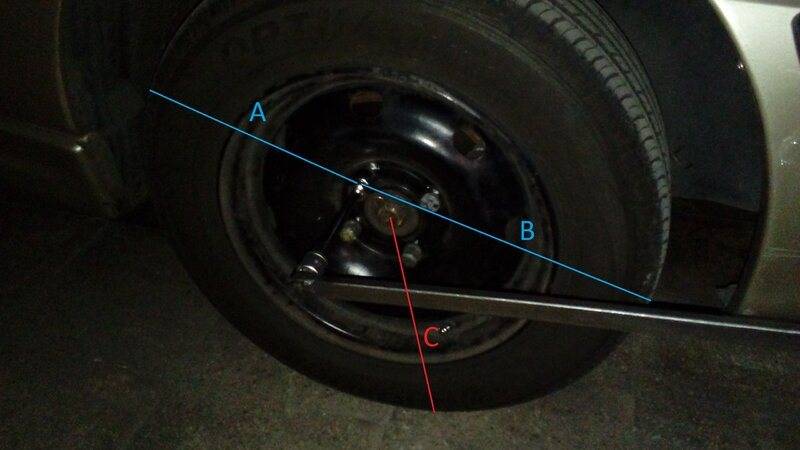

In the above picture of my car:

C = Tire radius = 0.289 meter

B = 0.339 meter

A = 0.238 meter

Therefore, B > C > A

If I set my torque wrench to 35 nm and torque the center bolt down, the force would be: 35 / 0.289 = 121 N

What about applying torque to one of lug nuts at the point between B & A?

How do you calculate force if I apply the same 35 nm to it?

35 / 0.339 = 103 N? or 35 / 0.238 = 147 N?

Which one is the answer and why?

In the above picture of my car:

C = Tire radius = 0.289 meter

B = 0.339 meter

A = 0.238 meter

Therefore, B > C > A

If I set my torque wrench to 35 nm and torque the center bolt down, the force would be: 35 / 0.289 = 121 N

What about applying torque to one of lug nuts at the point between B & A?

How do you calculate force if I apply the same 35 nm to it?

35 / 0.339 = 103 N? or 35 / 0.238 = 147 N?

Which one is the answer and why?

Last edited: