- #1

william497

- 5

- 2

I would like to understand the topic discussed in this thread more. https://www.physicsforums.com/threads/tipping-over-a-table-how-much-overhang.1012197/post-6598527

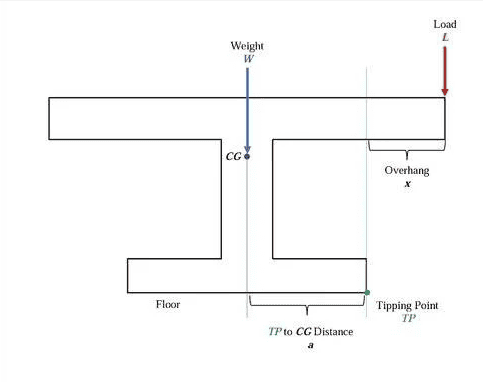

As I understand it, I can find the load required to tip the table can be calculated by this formula. L<W a/x

This is illustrated by this image.

What I don't understand is this. If I have a base that weighs 50kg's and a top that weighs 5kg's, total weight acting downwards through the CG of 55kg. It will take a substantial load to tip the table.

If I have a base that weighs 5kgs and a top (same diameter) that weighs 50kg, same total weight, but I know it will be much easier to tip the table because it is top heavy.

I don't see how the equation allows for the changing height of the center of gravity.

Am I interpreting the equation correctly? Or does the equation need to be adjusted to allow for the changing height of the center of gravity?

Any help is appreciated.

As I understand it, I can find the load required to tip the table can be calculated by this formula. L<W a/x

This is illustrated by this image.

What I don't understand is this. If I have a base that weighs 50kg's and a top that weighs 5kg's, total weight acting downwards through the CG of 55kg. It will take a substantial load to tip the table.

If I have a base that weighs 5kgs and a top (same diameter) that weighs 50kg, same total weight, but I know it will be much easier to tip the table because it is top heavy.

I don't see how the equation allows for the changing height of the center of gravity.

Am I interpreting the equation correctly? Or does the equation need to be adjusted to allow for the changing height of the center of gravity?

Any help is appreciated.