- #1

Ricky Bobby

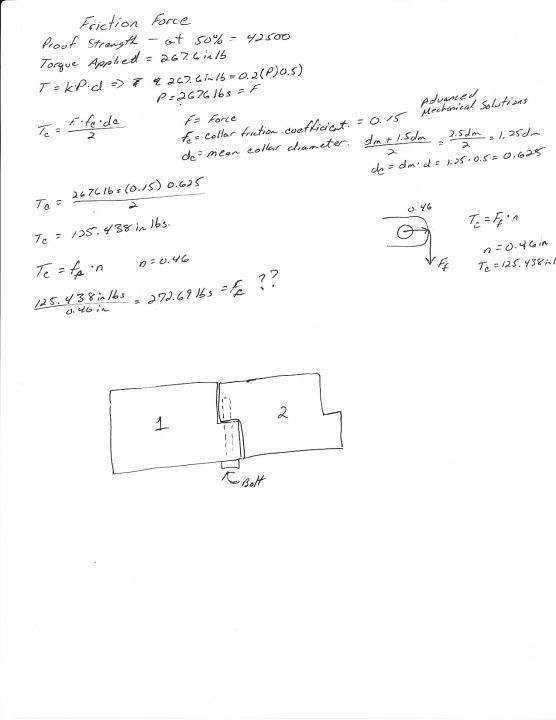

I think I have solved my problem for a friction force between a bolted assembly, or at least I think did. If a torque was given of 267.6 in-lbs and a constant of k=0.2 and the diameter(d) =0.5,

T=k*P*d should equal 267.6=0.2*P*0.5, resulting in P=2676lbs.

Then using the equation:

Tc=F*fc*dc/2

Where Tc=Torque

F= force =2676lbs

fc= collar friction coefficient =0.15

dc=mean collar diameter= dm+1.5dm/2=2.5dm/2=1.25dm: dc=dm*diameter=1.25*0.5=0.625

Tc=2676*0.15*0.625/2

Tc=125.438in-lbs

Then

Tc=ff*n

Tc=Torque=125.438in-lbs

ff=friction force

n=center of bolt hole to outer edge of part =0.46inches

125.438in-lbs=ff*0.46in

ff=272.69lbs?

Seems high for a frictional force for a 1/2 inch diameter bolt.

Any help is greatly appreciated. Thank you for any help you can lend.

T=k*P*d should equal 267.6=0.2*P*0.5, resulting in P=2676lbs.

Then using the equation:

Tc=F*fc*dc/2

Where Tc=Torque

F= force =2676lbs

fc= collar friction coefficient =0.15

dc=mean collar diameter= dm+1.5dm/2=2.5dm/2=1.25dm: dc=dm*diameter=1.25*0.5=0.625

Tc=2676*0.15*0.625/2

Tc=125.438in-lbs

Then

Tc=ff*n

Tc=Torque=125.438in-lbs

ff=friction force

n=center of bolt hole to outer edge of part =0.46inches

125.438in-lbs=ff*0.46in

ff=272.69lbs?

Seems high for a frictional force for a 1/2 inch diameter bolt.

Any help is greatly appreciated. Thank you for any help you can lend.