- #1

vinrow

- 2

- 0

I am in the process of designing an electric motorcycle, and would like to approximate the acceleration from various motors to inform my decision. I have written simple software to produce performance graphs, but my results seem a bit off - so i'd like to check my calculations.

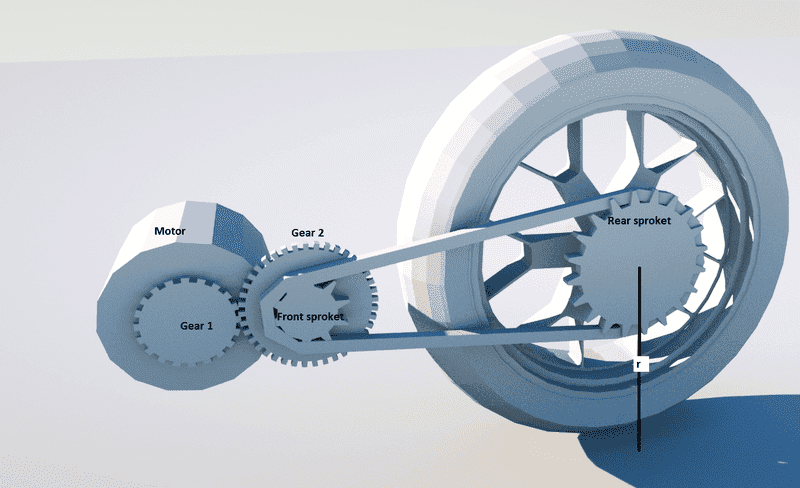

Here is the basic setup:

To simplify things I first calculated the effective radius of the wheel based on the gearing (as if driving the wheel directly from the motor):

r = Wheel radius / (Gear2/Gear1) * (RearSproket/FrontSproket)

Then used: Motor torque (T) = Fd and F=ma to get a = T/mr.

From this I calculate velocity at time intervals using: v = u+at and distance: S=ut + 0.5at^2

Now the bit where I think I'm going wrong (if not already) - Incorporating drag.

Using the drag equation: https://wikimedia.org/api/rest_v1/media/math/render/svg/144ce01ab76e5e8a0662dbf0f5b922abfa726e9c I am using a coefficient of 0.5, and area of 0.4m^2.

When calculating the torque at the rear wheel, I'm doing (Motor torque * 0.9) - (Drag force * r). The 0.9 is just to add a bit of mechanical loss. But I can't work out if I'm applying the drag correcly. Any input welcome.

Here is the basic setup:

To simplify things I first calculated the effective radius of the wheel based on the gearing (as if driving the wheel directly from the motor):

r = Wheel radius / (Gear2/Gear1) * (RearSproket/FrontSproket)

Then used: Motor torque (T) = Fd and F=ma to get a = T/mr.

From this I calculate velocity at time intervals using: v = u+at and distance: S=ut + 0.5at^2

Now the bit where I think I'm going wrong (if not already) - Incorporating drag.

Using the drag equation: https://wikimedia.org/api/rest_v1/media/math/render/svg/144ce01ab76e5e8a0662dbf0f5b922abfa726e9c I am using a coefficient of 0.5, and area of 0.4m^2.

When calculating the torque at the rear wheel, I'm doing (Motor torque * 0.9) - (Drag force * r). The 0.9 is just to add a bit of mechanical loss. But I can't work out if I'm applying the drag correcly. Any input welcome.