- #1

PhysicsTest

- 238

- 26

- TL;DR Summary

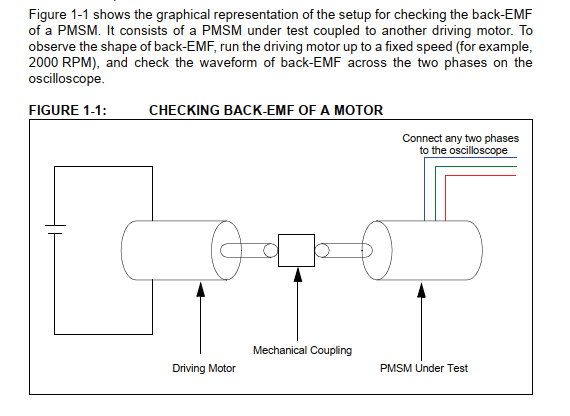

- Checking the backemf of BLDC motor on an oscilloscope.

I want to check the back emf of motor as shown in the article below

My question is does a normal probe will be sufficient or do I need a differential probe to check the back - EMF waveform?

My question is does a normal probe will be sufficient or do I need a differential probe to check the back - EMF waveform?