- #1

Jason Louison

- 70

- 6

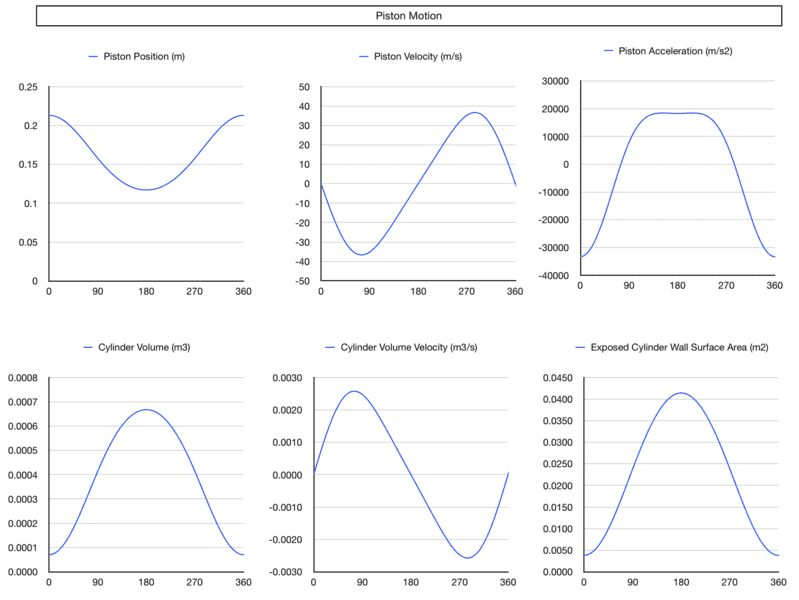

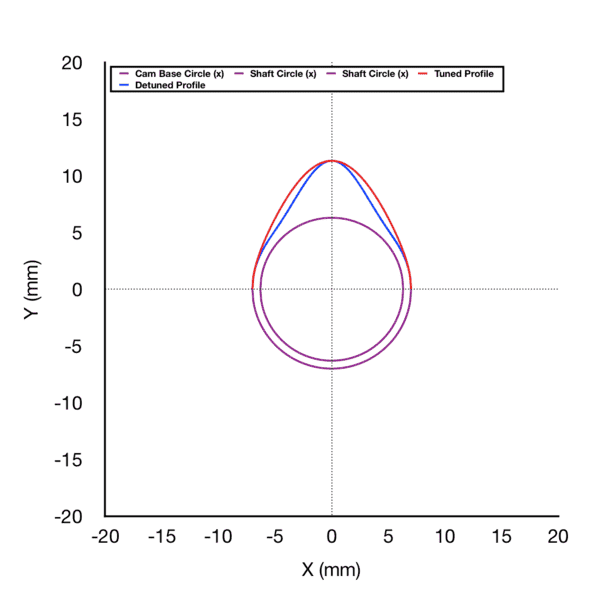

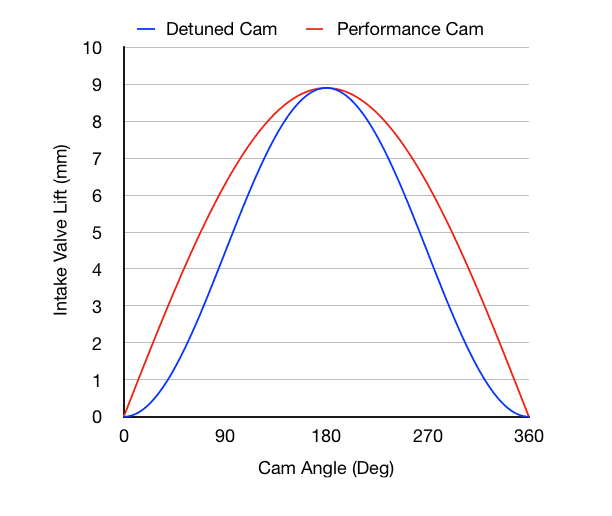

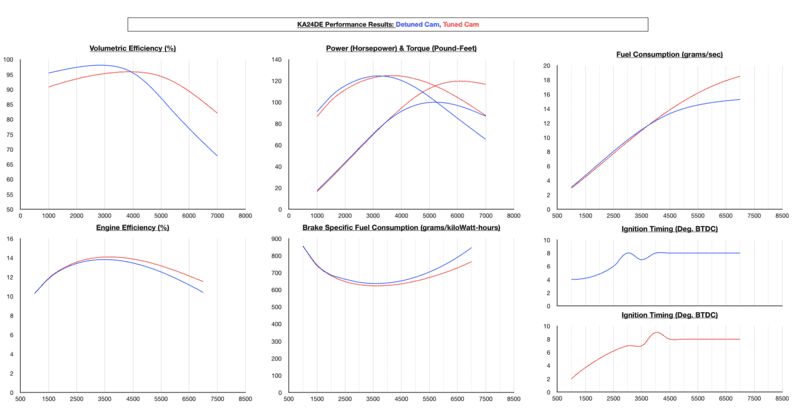

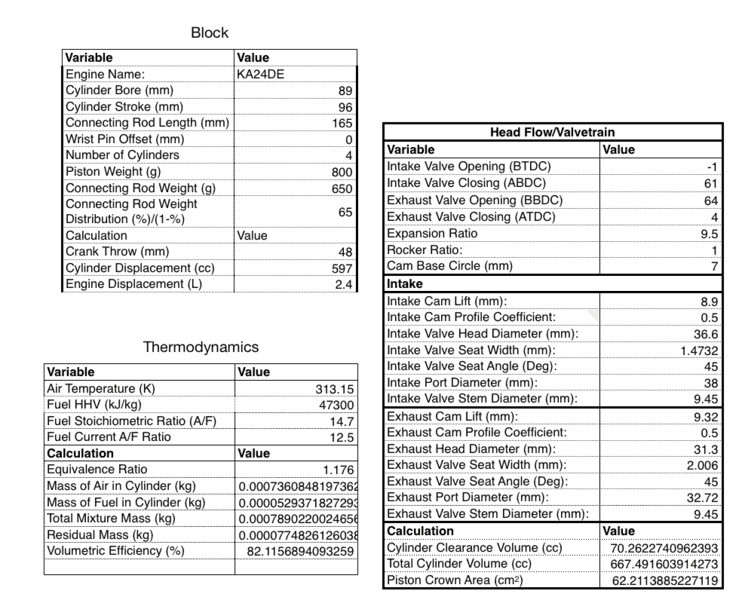

Hello Physics Forums! After almost a year of haggling and research, I think I have successfully made a engine simulation spreadsheet!  I have simulated the Nissan KA24DE Engine with two different cam profiles:

I have simulated the Nissan KA24DE Engine with two different cam profiles:

As far as I'm concerned, there is still a lot of work to be done. But I am very happy with the results so far. On the downside, The cylinder pressure function needs to be tweaked a bit, but I just wanted to share my findings so far with the physics forum!

Sources:

Heywood, J. B. Internal Combustion Engine Fundamentals. Mc Graw Hill International Editions, 1988.

Abu-Nada, Eiyad & Al-Hinti, Ismael & Al-sarkhi, A & Akash, Bilal. (2006). Thermodynamic modeling of spark-ignition engine: Effect of temperature dependent specific heats. International Communications in Heat and Mass Transfer. 33. 1264-1272. 10.1016/j.icheatmasstransfer.2006.06.014.

Kirkpatrick, Allan. Colorado State University Internal Combustion Engines Web Site, www.engr.colostate.edu/~allan/engines.html.

I have simulated the Nissan KA24DE Engine with two different cam profiles:

I have simulated the Nissan KA24DE Engine with two different cam profiles:As far as I'm concerned, there is still a lot of work to be done. But I am very happy with the results so far. On the downside, The cylinder pressure function needs to be tweaked a bit, but I just wanted to share my findings so far with the physics forum!

Sources:

Heywood, J. B. Internal Combustion Engine Fundamentals. Mc Graw Hill International Editions, 1988.

Abu-Nada, Eiyad & Al-Hinti, Ismael & Al-sarkhi, A & Akash, Bilal. (2006). Thermodynamic modeling of spark-ignition engine: Effect of temperature dependent specific heats. International Communications in Heat and Mass Transfer. 33. 1264-1272. 10.1016/j.icheatmasstransfer.2006.06.014.

Kirkpatrick, Allan. Colorado State University Internal Combustion Engines Web Site, www.engr.colostate.edu/~allan/engines.html.

Attachments

-

Screen Shot 2018-02-11 at 5.24.13 PM.png21.2 KB · Views: 902

Screen Shot 2018-02-11 at 5.24.13 PM.png21.2 KB · Views: 902 -

Screen Shot 2018-02-11 at 5.24.58 PM.png11 KB · Views: 845

Screen Shot 2018-02-11 at 5.24.58 PM.png11 KB · Views: 845 -

Screen Shot 2018-02-11 at 5.25.05 PM.png9.4 KB · Views: 859

Screen Shot 2018-02-11 at 5.25.05 PM.png9.4 KB · Views: 859 -

Screen Shot 2018-02-11 at 5.25.24 PM.png17.6 KB · Views: 738

Screen Shot 2018-02-11 at 5.25.24 PM.png17.6 KB · Views: 738 -

Screen Shot 2018-02-11 at 5.51.04 PM.png54.2 KB · Views: 728

Screen Shot 2018-02-11 at 5.51.04 PM.png54.2 KB · Views: 728

Last edited by a moderator: