@jim hardy laid it out well.

Abdul Wali said:

more energy consumption of the controller

Not the controller itself, but this may be (and often is) true of the controlled process.

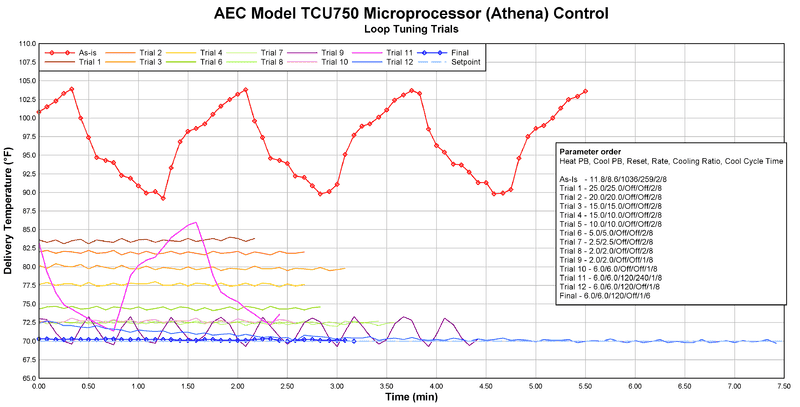

Consider a TCU (Temperature Control Unit) consisting of a centrifugal pump, 12 kW resistance heater, and a cooling solenoid connected to a 50°F chilled water source for 'direct injection' cooling. In temperature trending below, 'As-Is' loop tuning had the output slamming 'rail-to-rail' between 100% heating, and 100% cooling with temperature oscillating between 90°F to 104°F (14°F peak-to-peak variation) for a 70°F setpoint. After 'final' tuning, output remained between 30% cooling to 40% cooling providing a process temperature ranging between 69.6°F to 70.4°F (0.8°F peak-to-peak variation).

This controller has somewhat peculiar parameters including a separate term for cooling proportional gain (typically, commercial temperature controllers have a heating prop gain, and a multiplier term derived from it for cooling prop gain) and a 'Cooling Ratio' term that, as it turned out, was a range matching scheme so anything from chilled water to hot oil cooling sources could be used. 'Reset' and 'Rate' are scaled in seconds, and are an older terminology used to denote integrating and derivative gains. At the time I didn't have a copy of the manual, and was conducting multiple trials using different tuning parameters to better understand how they worked. Data collection for this trend continued to the end of my work shift. The 'final' reset (integrating) time of 120 seconds shown in the table is too high (note how long 'trial 12' temperature took to converge to setpoint), and was touched up the next day to 40 seconds.

My interest then was to minimize temperature swing, and I was collecting data by scrawling it into a notebook every 5 seconds so didn't bother (nor had time) to collect % output information. The 'humpedness' of 'As-Is' temperature variation suggests cooling on-time % wasn't symmetrical with heating % (it was probably more like 30% cooling/70% heating rather than 50%/50%), but for the purpose of cost estimation let's pretend it was a 50:50 split.

Energy cost for a 12 kW heater at $0.10 USD/hour is $1.20/hour at 100% heating. It is difficult to estimate an accurate value for cooling, what with cooling tower and process pump and chiller compressor energy, maintenance, makeup water, treatment chemical, and other costs, but a kWh of chilled water cooling ends up costing more than a kWh of electric heating. For now, let's guess $1.50 an hour for cooling.

An hour of 'As-Is' temperature control operation at 50% heating/50% cooling would be (0.5*$1.20)+(0.5*$1.50), or $1.35 an hour. After tuning, output no longer traversed into the heating side, and averaged 35% cooling (0.35*$1.50), or about $0.53 an hour.

In this case, improper loop tuning cost approximately $0.82 extra per operating hour.