- #1

1rel

- 43

- 3

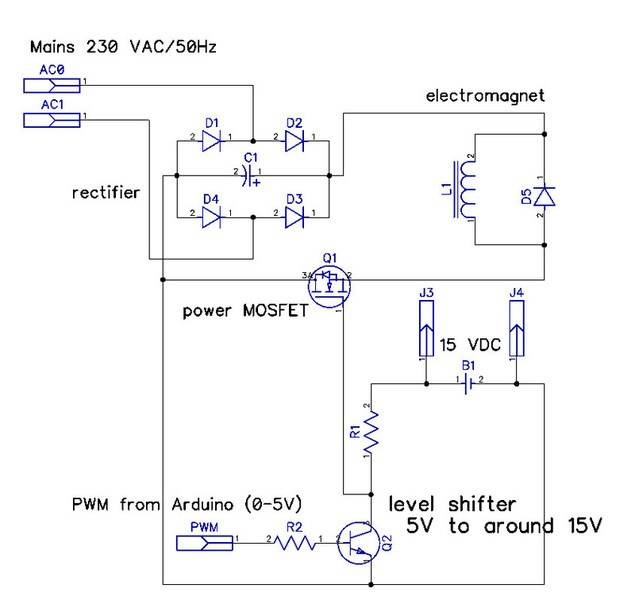

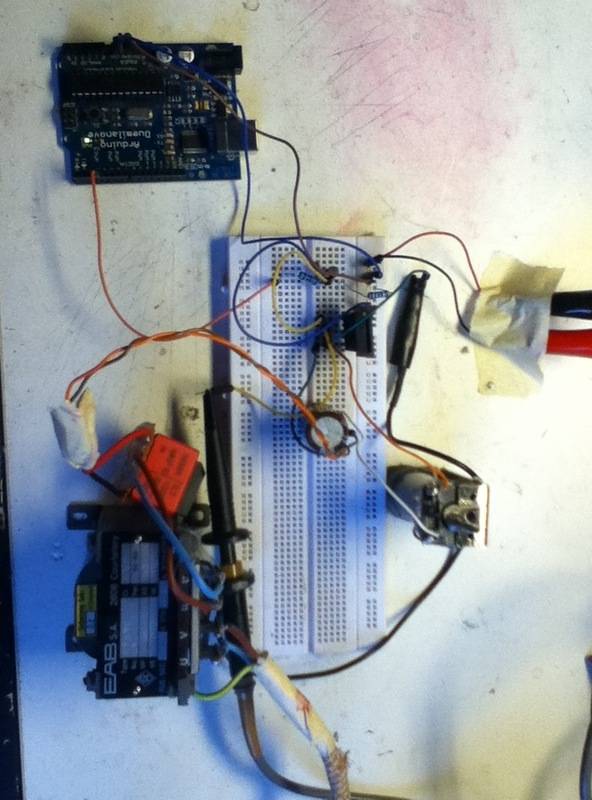

Recently, I was trying to control the strength of an electromagnet with PWM over a MOSFET or IGBT with an Arduino/microcontroller. It worked but I burnt multiple MOSFETs/IGBTs while testing it, after certain time... so something must have gone wrong...

I'd like to build a simple circuit, to control an electromagnet in strength in polarity from a microcontroller. But since I'm not very experienced in (serious) electrical engineering, I have troubles chooosing the right parts... Some questions I have right now:

1) Is it okay to choose a MOSFET or IGBT to control the current to the magnet? PWM will turn on/off the magnet with quite high frequency... actually I would rather like to be able to change the current without switching at all, but I heared that it will heat up the MOSFET/IGBT much faster when it's not turned off/on fully... Actually heat was probably also the problem in my test setup. Although I used a heat sink, it got quite hot (I've tested those two chips: FGL40N120AND, IRFP260, I've got from an old uninterruptible power supply) - they have quite high ratings, but stopped working at a certain point. I've also placed a snubber diode antiparallel to the coil... so probably it was just the heat. - Also, the magnet still produced some acoustic noise, although the PWM frequency was quite high... it was also recognizable when holding metal parts close to the magnet... some resonance probably. With pure DC this wouldn't be the case I guess...

2) Is it a good idea to use a H-bridge (e.g. L298?) to change the polarity of the magnet? And is it wise to use 4 (logic level) MOSFETs to it? - E.g. STP16N65M5 ..it's going to be expensive... Or is there simpler way to do it?

3) Actually I do not only need one magnet in the end, but multiple of them. So, I was thinking about using a PWM driver board (e.g. that one with a PCA9685). So I was thinking out using an H-Bridge, protection diode for every magnet, and connecting it to the PWM driver IC...

4) Do you have experience with winding your own coils? What material is best for the core, soft iron rods, and copper wire... I'd like to make ~16 of those magnets, and work in a secure area at around 12V, but still generated reasonable strong magnets that can easily move an iron balls of 10mm in diameter...That was about my test circuit so far:

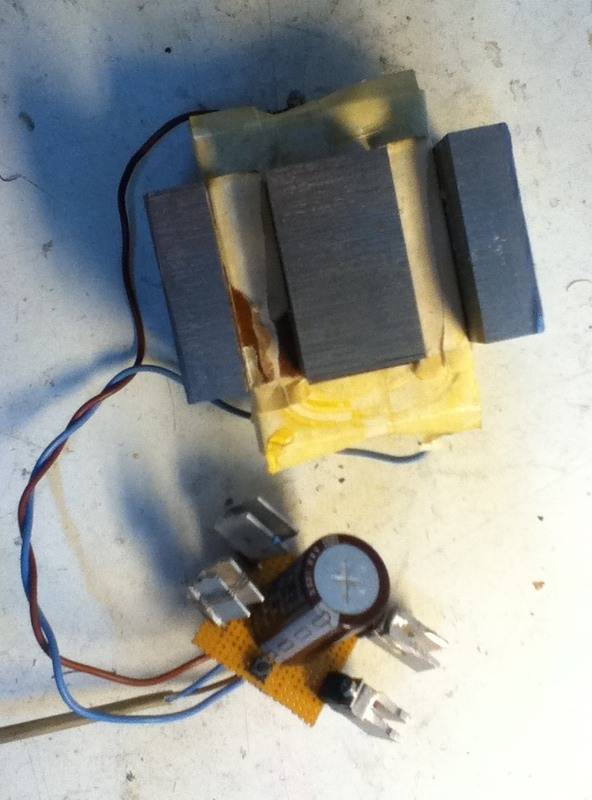

In the smaller version, I've used a transformer, and got about 100 V DC for the magnet.

In the larger version, I've powered it directly from the mains, without a transformer in between, and got 317 V DC to switch (which might be stupid!):

In my test setup, I've used different kind of coils. One from an old relay, and a huge one from a microwave oven transformer (core + only secondary winding). As soon as I connected the bigger one (with ~100 Ohm resistance and pobably >1000 turns) directly to IGBT at 317 V (rectified directly from the mains), it worked for a couple of minutes, but then burnt the IGBT... this was the most extreme scenario. The magnet was very powerful, it even distored the display on my oscilloscope... and somehow almost destroyed my bench power supply (burnt a capacitor in there).

Any hints would be much appreciated! At the moment it's all trial'n'error here ;)

I'd like to build a simple circuit, to control an electromagnet in strength in polarity from a microcontroller. But since I'm not very experienced in (serious) electrical engineering, I have troubles chooosing the right parts... Some questions I have right now:

1) Is it okay to choose a MOSFET or IGBT to control the current to the magnet? PWM will turn on/off the magnet with quite high frequency... actually I would rather like to be able to change the current without switching at all, but I heared that it will heat up the MOSFET/IGBT much faster when it's not turned off/on fully... Actually heat was probably also the problem in my test setup. Although I used a heat sink, it got quite hot (I've tested those two chips: FGL40N120AND, IRFP260, I've got from an old uninterruptible power supply) - they have quite high ratings, but stopped working at a certain point. I've also placed a snubber diode antiparallel to the coil... so probably it was just the heat. - Also, the magnet still produced some acoustic noise, although the PWM frequency was quite high... it was also recognizable when holding metal parts close to the magnet... some resonance probably. With pure DC this wouldn't be the case I guess...

2) Is it a good idea to use a H-bridge (e.g. L298?) to change the polarity of the magnet? And is it wise to use 4 (logic level) MOSFETs to it? - E.g. STP16N65M5 ..it's going to be expensive... Or is there simpler way to do it?

3) Actually I do not only need one magnet in the end, but multiple of them. So, I was thinking about using a PWM driver board (e.g. that one with a PCA9685). So I was thinking out using an H-Bridge, protection diode for every magnet, and connecting it to the PWM driver IC...

4) Do you have experience with winding your own coils? What material is best for the core, soft iron rods, and copper wire... I'd like to make ~16 of those magnets, and work in a secure area at around 12V, but still generated reasonable strong magnets that can easily move an iron balls of 10mm in diameter...That was about my test circuit so far:

In the smaller version, I've used a transformer, and got about 100 V DC for the magnet.

In the larger version, I've powered it directly from the mains, without a transformer in between, and got 317 V DC to switch (which might be stupid!):

In my test setup, I've used different kind of coils. One from an old relay, and a huge one from a microwave oven transformer (core + only secondary winding). As soon as I connected the bigger one (with ~100 Ohm resistance and pobably >1000 turns) directly to IGBT at 317 V (rectified directly from the mains), it worked for a couple of minutes, but then burnt the IGBT... this was the most extreme scenario. The magnet was very powerful, it even distored the display on my oscilloscope... and somehow almost destroyed my bench power supply (burnt a capacitor in there).

Any hints would be much appreciated! At the moment it's all trial'n'error here ;)

Last edited: