- #1

Travis T

- 18

- 2

- TL;DR Summary

- Factor affecting compression spring oscillating effect

Hi all,

I'm studying the compression spring design issue that occurred in a machine design application.

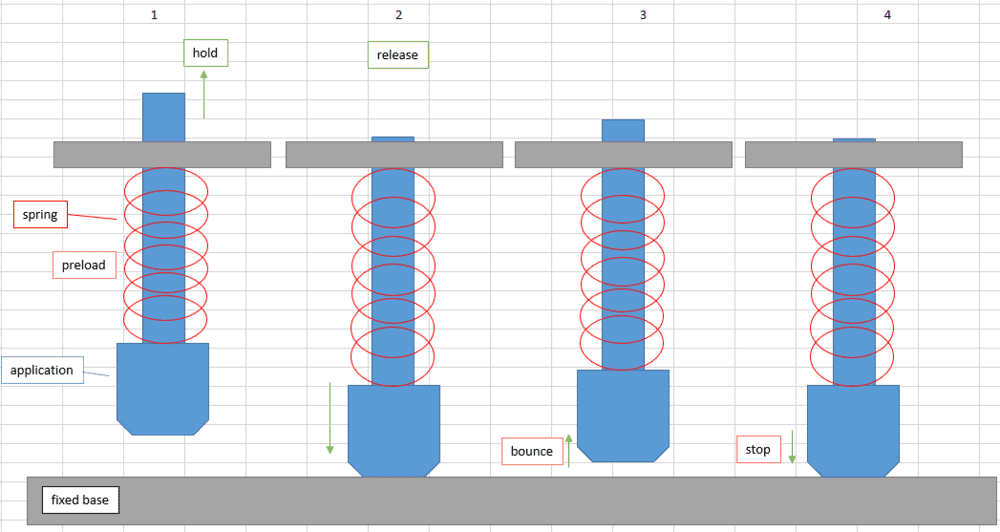

As illustrated below, spring is bouncing or oscillating after impact to a stopping surface (1 -> 2 -> 3 -> 4) and eventually stop after few bounces.

Ideal case for this application is to eliminate the bouncing effect (1 -> 4).

Assuming only enable changes in spring design, my question is:

What properties should I look into for reducing the bouncing effect? eg. deduct spring constant, reduce preload spring force, increase spring force?

I'm studying the compression spring design issue that occurred in a machine design application.

As illustrated below, spring is bouncing or oscillating after impact to a stopping surface (1 -> 2 -> 3 -> 4) and eventually stop after few bounces.

Ideal case for this application is to eliminate the bouncing effect (1 -> 4).

Assuming only enable changes in spring design, my question is:

What properties should I look into for reducing the bouncing effect? eg. deduct spring constant, reduce preload spring force, increase spring force?