- #1

hackhard

- 183

- 15

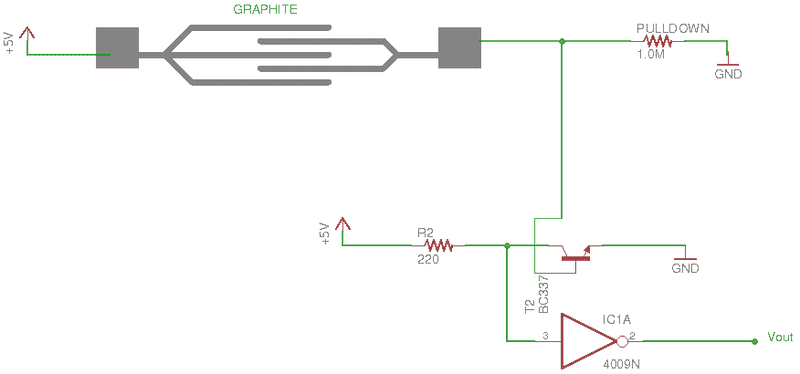

graphite has high conductivity , so i though of making a touch button out of a pencil drawn pattern on the wall.the pattern is shown below.

when not touched -resistance between ends of the pattern >200Mohm (exceeds dmm limit)

when fully pressed - resistance between ends of the pattern = 1.3 Mohm.

but Vout rises after delay or falls after delay of some 100 ms.due to high impedance

this pattern connects skin resistances in parallel

can someone suggest a better pattern ( of lower end to end resistance) ?

for faster response

when not touched -resistance between ends of the pattern >200Mohm (exceeds dmm limit)

when fully pressed - resistance between ends of the pattern = 1.3 Mohm.

but Vout rises after delay or falls after delay of some 100 ms.due to high impedance

this pattern connects skin resistances in parallel

can someone suggest a better pattern ( of lower end to end resistance) ?

for faster response

Last edited: