- #1

friscoboya

- 6

- 1

Hello

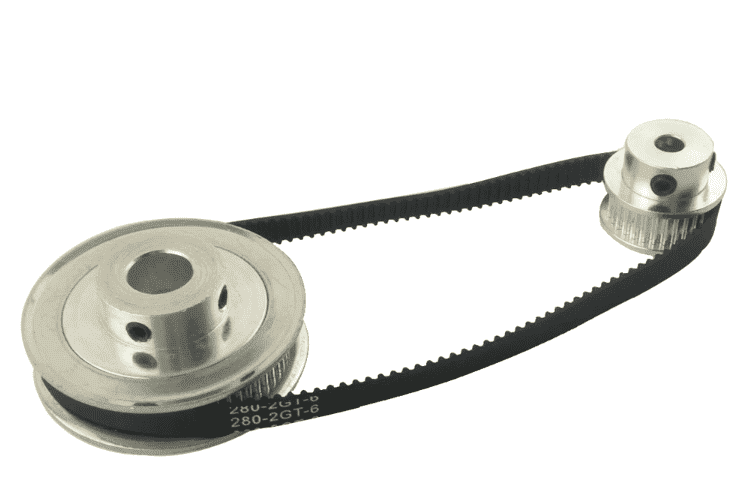

I am designing a shaft and it will be powered via belt pulley system. The ideal RPM of the shaft is 8000 RPM. How do I calculate the natural frequency of the timing belt to ensure resonance is never met? From what I read online it has to do with belt pretension, but even then I am little lost. Equations and links would be helpful.

Thank you

I am designing a shaft and it will be powered via belt pulley system. The ideal RPM of the shaft is 8000 RPM. How do I calculate the natural frequency of the timing belt to ensure resonance is never met? From what I read online it has to do with belt pretension, but even then I am little lost. Equations and links would be helpful.

Thank you