- #1

psugumaran

- 3

- 0

Hi,

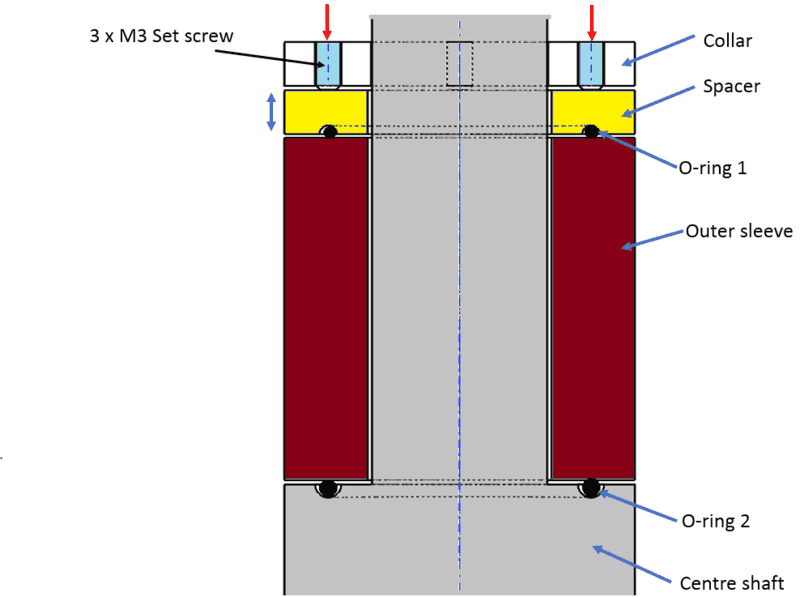

I am working on a problem where I have to find the tightening torque required for rotating the outer sleeve. The Outer sleeve is rotated by human hand ( One hand operation) hence the sleeve torque feel is determined by the set screw.

Problem statement: Please refer the image. O-ring 1 at the spacer will compress the Outer sleeve against O-ring 2 by means of tightening the set screws in the collar. The spacer is movable (floating position) and collar is fastened with shaft (fixed position). When the set screw is tighten, the spacer moves and compress the O-ring (1) against outer sleeve.

I have to calculate, How much torque is required for set screw to tighten so that sleeve will be rotated against the O-rings (1&2). Consider it is a dry condition

Set screw = 3 nos (M3)

O-ring material = Viton

Sleeve material = Aluminum 6061-T6

Maximum Torque applied by human hand (One hand) = 9000 N-mm

Thanks in advance.

I am working on a problem where I have to find the tightening torque required for rotating the outer sleeve. The Outer sleeve is rotated by human hand ( One hand operation) hence the sleeve torque feel is determined by the set screw.

Problem statement: Please refer the image. O-ring 1 at the spacer will compress the Outer sleeve against O-ring 2 by means of tightening the set screws in the collar. The spacer is movable (floating position) and collar is fastened with shaft (fixed position). When the set screw is tighten, the spacer moves and compress the O-ring (1) against outer sleeve.

I have to calculate, How much torque is required for set screw to tighten so that sleeve will be rotated against the O-rings (1&2). Consider it is a dry condition

Set screw = 3 nos (M3)

O-ring material = Viton

Sleeve material = Aluminum 6061-T6

Maximum Torque applied by human hand (One hand) = 9000 N-mm

Thanks in advance.